ArtiSynth Modeling Guide

Last update: June, 2025

Contents

- Preface

- 1 ArtiSynth Overview

- 2 Supporting classes

-

3 Mechanical Models I

- 3.1 Springs and particles

-

3.2 Rigid bodies

- 3.2.1 Frame markers

- 3.2.2 Example: a simple rigid body-spring model

- 3.2.3 Creating rigid bodies

- 3.2.4 Pose and velocity

- 3.2.5 Inertia and the surface mesh

- 3.2.6 Coordinate frames and the center of mass

- 3.2.7 Damping parameters

- 3.2.8 Rendering rigid bodies

- 3.2.9 Multiple meshes

- 3.2.10 Example: a composite rigid body

- 3.3 Mesh components

-

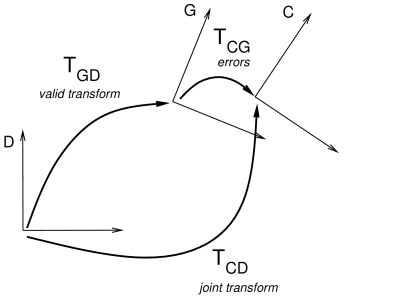

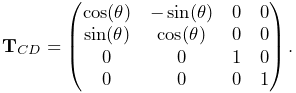

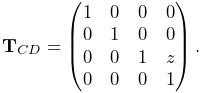

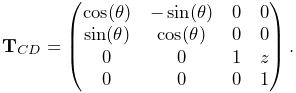

3.4 Joints and connectors

- 3.4.1 Joints and coordinate frames

- 3.4.2 Joint coordinates, constraints, and errors

- 3.4.3 Creating joints

- 3.4.4 Working with coordinates

- 3.4.5 Coordinate limits and locking

- 3.4.6 Example: a simple hinge joint

- 3.4.7 Constraint forces

- 3.4.8 Compliance and regularization

- 3.4.9 Example: an overconstrained linkage

- 3.4.10 Rendering joints

-

3.5 Joint components

- 3.5.1 Hinge joint

- 3.5.2 Slider joint

- 3.5.3 Cylindrical joint

- 3.5.4 Slotted hinge joint

- 3.5.5 Universal joint

- 3.5.6 Skewed universal joint

- 3.5.7 Gimbal joint

- 3.5.8 Spherical joint

- 3.5.9 Planar joint

- 3.5.10 Planar translation joint

- 3.5.11 Ellipsoid joint

- 3.5.12 Solid joint

- 3.5.13 Planar Connector

- 3.5.14 Segmented Planar Connector

- 3.5.15 Legacy Joints

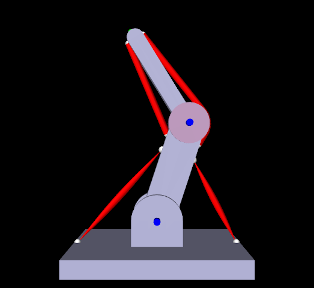

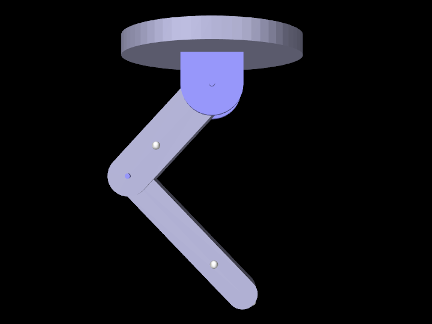

- 3.5.16 Example: A multijointed arm

- 3.6 Frame springs

- 3.7 Other point-based forces

- 3.8 Attachments

-

4 Mechanical Models II

- 4.1 Simulation control properties

- 4.2 Units

- 4.3 Render properties

- 4.4 Custom rendering

- 4.5 Point-to-point muscles, tendons and ligaments

- 4.6 Distance Grids and Components

- 4.7 Transforming geometry

- 4.8 General component arrangements

- 4.9 Custom Joints

-

5 Simulation Control

- 5.1 Control Panels

- 5.2 Custom properties

- 5.3 Controllers and monitors

-

5.4 Probes

- 5.4.1 Numeric probe structure

- 5.4.2 Creating probes in code

- 5.4.3 Example: probes connected to SimpleMuscle

- 5.4.4 Data file format

- 5.4.5 Adding input probe data in code

- 5.4.6 Setting data from text or CSV files and other probes

- 5.4.7 Tracing probes

- 5.4.8 Position probes

- 5.4.9 Velocity probes

- 5.4.10 Example: controlling a point and frame

- 5.4.11 Numeric monitor probes

- 5.4.12 Numeric control probes

- 5.5 Working with TRC data

- 5.6 Application-Defined Menu Items

-

6 Finite Element Models

- 6.1 Overview

- 6.2 FEM model creation

- 6.3 FEM Geometry

-

6.4 Connecting FEM models to other components

- 6.4.1 Connecting nodes to rigid bodies or particles

- 6.4.2 Example: connecting a beam to a block

- 6.4.3 Connecting nodes directly to elements

- 6.4.4 Example: connecting two FEMs together

- 6.4.5 Finding which nodes to attach

- 6.4.6 Selecting nodes in the viewer

- 6.4.7 Example: two bodies connected by an FEM “spring”

- 6.4.8 Nodal-based attachments

- 6.4.9 Example: element vs. nodal-based attachments

- 6.5 FEM markers

- 6.6 Frame attachments

- 6.7 Incompressibility

- 6.8 Varying and augmenting material behaviors

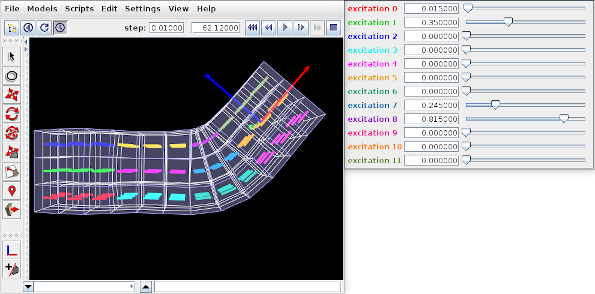

- 6.9 Muscle activated FEM models

-

6.10 Material types

- 6.10.1 Linear

-

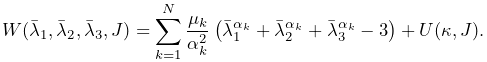

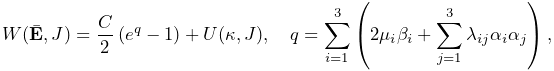

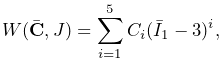

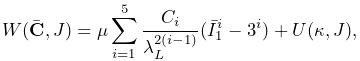

6.10.2 Hyperelastic materials

- 6.10.2.1 St Venant-Kirchoff material

- 6.10.2.2 Neo-Hookean material

- 6.10.2.3 Incompressible neo-Hookean material

- 6.10.2.4 Mooney-Rivlin material

- 6.10.2.5 Ogden material

- 6.10.2.6 Fung orthotropic material

- 6.10.2.7 Yeoh material

- 6.10.2.8 Arruda-Boyce material

- 6.10.2.9 Veronda-Westmann material

- 6.10.2.10 Incompressible material

- 6.10.3 Muscle materials

- 6.11 Stress, strain and strain energy

- 6.12 Rendering and Visualizations

- 7 Fields

- 8 Contact and Collision

- 9 Muscle Wrapping and Via Points

-

10 Inverse Simulation

- 10.1 Overview

-

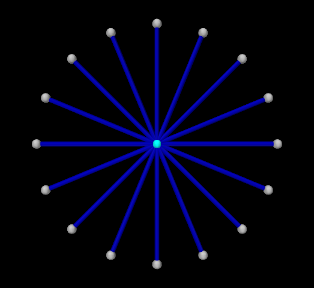

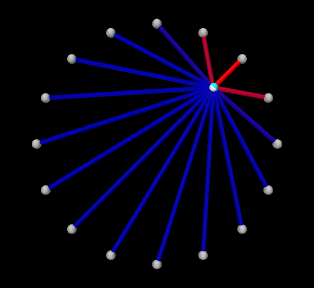

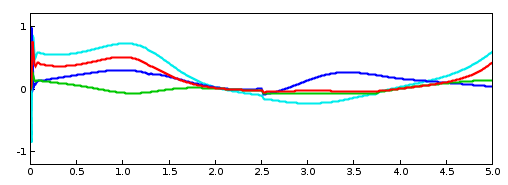

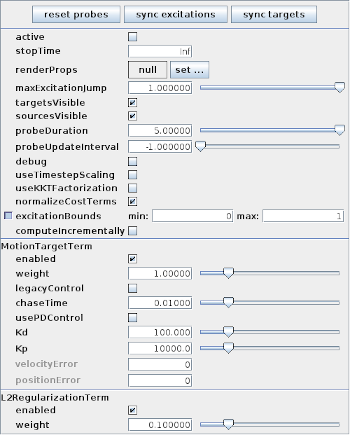

10.2 Tracking controller components

- 10.2.1 Exciters

- 10.2.2 Motion targets

- 10.2.3 Regularization

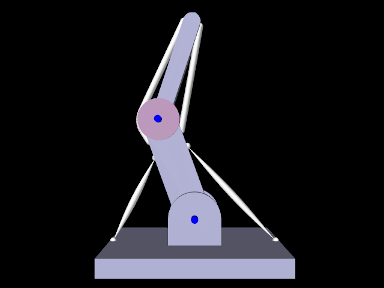

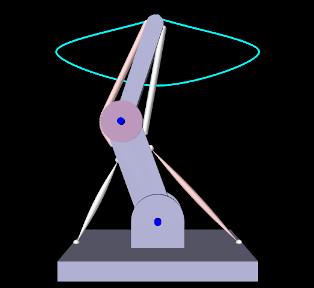

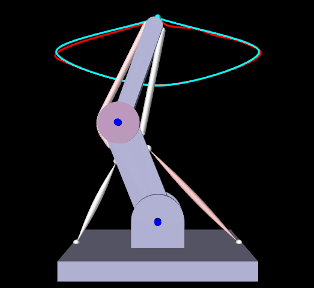

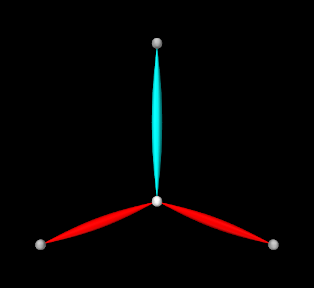

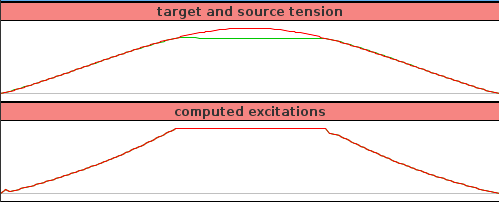

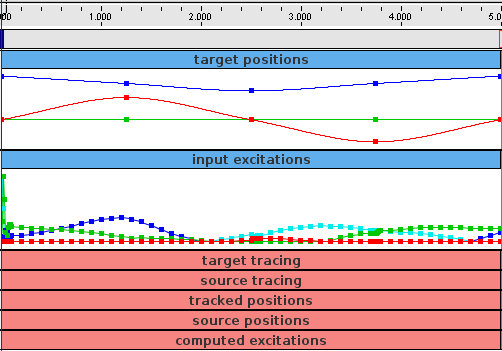

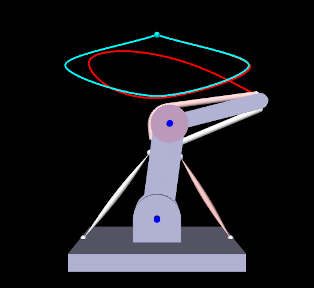

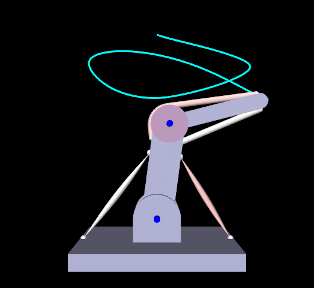

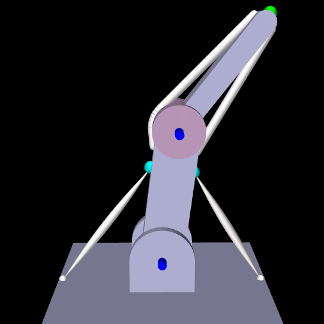

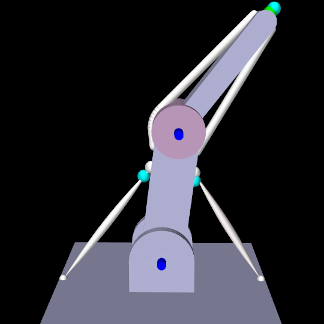

- 10.2.4 Example: controlling ToyMuscleArm

- 10.2.5 Example: controlling an FEM muscle model

- 10.2.6 Force effector targets

- 10.2.7 Example: controlling tension in a spring

- 10.2.8 Target components

- 10.2.9 Point and frame exciters

- 10.2.10 Example: controlling ToyMuscleArm with FrameExciters

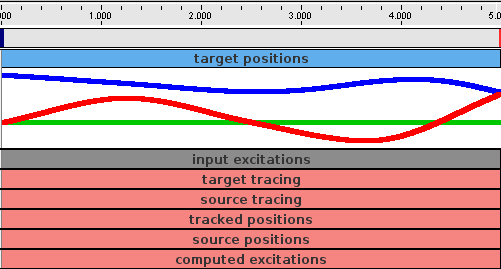

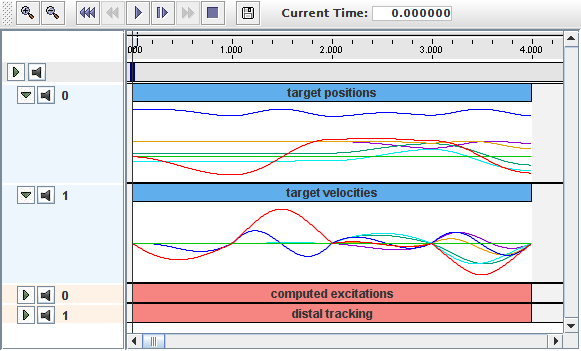

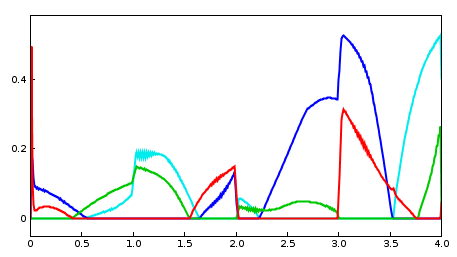

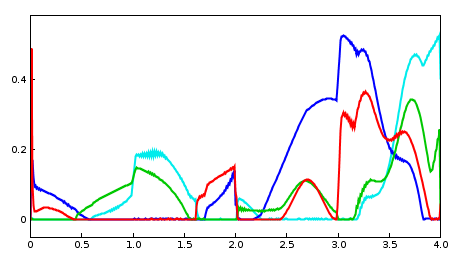

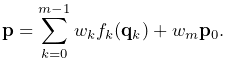

- 10.3 Tracking controller structure and settings

- 10.4 Managing probes and control panels

- 10.5 Inverse kinematics

- 10.6 Caveats and limitations

- 11 Skinning

- 12 Importing OpenSim Models

- 13 DICOM Images

- A Mathematical Review

Preface

This guide describes how to create mechanical and biomechanical models in ArtiSynth using its Java API. Detailed information on how to use the ArtiSynth GUI for model visualization, navigation and simulation control is given in the ArtiSynth User Interface Guide. It is also possible to interface ArtiSynth with, or run it under, MATLAB. For information on this, see the guide Interfacing ArtiSynth to MATLAB.

Information on how to install and configure ArtiSynth is given in the installation guides for Windows, MacOS, and Linux.

It is assumed that the reader is familiar with basic Java programming, including variable assignment, control flow, exceptions, functions and methods, object construction, inheritance, and method overloading. Some familiarity with the basic I/O classes defined in java.io.*, including input and output streams and the specification of file paths using File, as well as the collection classes ArrayList and LinkedList defined in java.util.*, is also assumed.

How to read this guide

Section 1 offers a general overview of ArtiSynth’s software design, and briefly describes the algorithms used for physical simulation (Section 1.2). The latter section may be skipped on first reading. A more comprehensive overview paper is available online.

The remainder of the manual gives details instructions on how to build various types of mechanical and biomechanical models. Sections 3 and 4 give detailed information about building general mechanical models, involving particles, springs, rigid bodies, joints, constraints, and contact. Section 5 describes how to add control panels, controllers, and input and output data streams to a simulation. Section 6 describes how to incorporate finite element models. The required mathematics is reviewed in Section A.

If time permits, the reader will profit from a top-to-bottom read. However, this may not always be necessary. Many of the sections contain detailed examples, all of which are available in the package artisynth.demos.tutorial and which may be run from ArtiSynth using Models > All demos > tutorials. More experienced readers may wish to find an appropriate example and then work backwards into the text and preceding sections for any needed explanatory detail.

Chapter 1 ArtiSynth Overview

ArtiSynth is an open-source, Java-based system for creating and simulating mechanical and biomechanical models, with specific capabilities for the combined simulation of rigid and deformable bodies, together with contact and constraints. It is presently directed at application domains in biomechanics, medicine, physiology, and dentistry, but it can also be applied to other areas such as traditional mechanical simulation, ergonomic design, and graphical and visual effects.

1.1 System structure

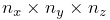

An ArtiSynth model is composed of a hierarchy of models and model components which are implemented by various Java classes. These may include sub-models (including finite element models), particles, rigid bodies, springs, connectors, and constraints. The component hierarchy may be in turn connected to various agent components, such as control panels, controllers and monitors, and input and output data streams (i.e., probes), which have the ability to control and record the simulation as it advances in time. Agents are presented in more detail in Section 5.

The models and agents are collected together within a top-level component known as a root model. Simulation proceeds under the control of a scheduler, which advances the models through time using a physics simulator. A rich graphical user interface (GUI) allows users to view and edit the model hierarchy, modify component properties, and edit and temporally arrange the input and output probes using a timeline display.

1.1.1 Model components

Every ArtiSynth component is an instance of ModelComponent. When connected to the hierarchy, it is assigned a unique number relative to its parent; the parent and number can be obtained using the methods getParent() and getNumber(), respectively. Components may also be assigned a name (using setName()) which is then returned using getName().

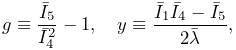

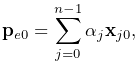

A component’s number is not the same as its index. The index gives the component’s sequential list position within the parent, and is always in the range

, where

is the parent’s number of child components. While indices and numbers frequently are the same, they sometimes are not. For example, a component’s number is guaranteed to remain unchanged as long as it remains attached to its parent; this is different from its index, which will change if any preceding components are removed from the parent. For example, if we have a set of components with numbers

0 1 2 3 4 5and components 2 and 4 are then removed, the remaining components will have numbers

0 1 3 5whereas the indices will be 0 1 2 3. This consistency of numbers is why they are used to identify components.

A sub-interface of ModelComponent includes CompositeComponent, which contains child components. A ComponentList is a CompositeComponent which simply contains a list of other components (such as particles, rigid bodies, sub-models, etc.).

Components which contain state information (such as position and velocity) should extend HasState, which provides the methods getState() and setState() for saving and restoring state.

A Model is a sub-interface of CompositeComponent and HasState that contains the notion of advancing through time and which implements this with the methods initialize(t0) and advance(t0, t1, flags), as discussed further in Section 1.1.4. The most common instance of Model used in ArtiSynth is MechModel (Section 1.1.5), which is the top-level container for a mechanical or biomechanical model.

1.1.2 The RootModel

The top-level component in the hierarchy is the root model, which is a subclass of RootModel and which contains a list of models along with lists of agents used to control and interact with these models. The component lists in RootModel include:

models top-level models of the component hierarchy inputProbes input data streams for controlling the simulation controllers functions for controlling the simulation monitors functions for observing the simulation outputProbes output data streams for observing the simulation

Each agent may be associated with a specific top-level model.

1.1.3 Component path names

The names and/or numbers of a component and its ancestors can be used to form a component path name. This path has a construction analogous to Unix file path names, with the ’/’ character acting as a separator. Absolute paths start with ’/’, which indicates the root model. Relative paths omit the leading ’/’ and can begin lower down in the hierarchy. A typical path name might be

/models/JawHyoidModel/axialSprings/lad

For nameless components in the path, their numbers can be used instead. Numbers can also be used for components that have names. Hence the path above could also be represented using only numbers, as in

/0/0/1/5

although this would most likely appear only in machine-generated output.

1.1.4 Model advancement

ArtiSynth simulation proceeds by advancing all of the root model’s top-level models through a sequence of time steps. Every time step is achieved by calling each model’s advance() method:

This method advances the model from time t0 to time t1, performing whatever physical simulation is required (see Section 1.2). The method may optionally return a StepAdjustment indicating that the step size (t1 - t0) was too large and that the advance should be redone with a smaller step size.

The root model has it’s own advance(), which in turn calls the advance method for all of the top-level models, in sequence. The advance of each model is surrounded by the application of whatever agents are associated with that model. This is done by calling the agent’s apply() method:

Agents not associated with a specific model are applied before (or after) the advance of all other models.

More precise details about model advancement are given in the ArtiSynth Reference Manual.

1.1.5 MechModel

Most ArtiSynth applications contain a single top-level model which is an instance of MechModel. This is aCompositeComponent that may (recursively) contain an arbitrary number of mechanical components, including finite element models, other MechModels, particles, rigid bodies, constraints, attachments, and various force effectors. The MechModel advance() method invokes a physics simulator that advances these components forward in time (Section 1.2).

For convenience each MechModel contains a number of predefined containers for different component types, including:

particles 3 DOF particles points other 3 DOF points rigidBodies 6 DOF rigid bodies frames other 6 DOF frames axialSprings point-to-point springs connectors joint-type connectors between bodies constrainers general constraints forceEffectors general force-effectors attachments attachments between dynamic components renderables renderable components (for visualization only)

Each of these is a child component of MechModel and is implemented as a ComponentList. Special methods are provided for adding and removing items from them. However, applications are not required to use these containers, and may instead create any component containment structure that is appropriate. If not used, the containers will simply remain empty.

1.2 Physics simulation

Only a brief summary of ArtiSynth physics simulation is described here. Full details are given in [11] and in the related overview paper.

For purposes of physics simulation, the components of a MechModel are grouped as follows:

- Dynamic components

-

Components, such as a particles and rigid bodies, that contain position and velocity state, as well as mass. All dynamic components are instances of the Java interface DynamicComponent. - Force effectors

-

Components, such as springs or finite elements, that exert forces between dynamic components. All force effectors are instances of the Java interface ForceEffector. - Constrainers

-

Components that enforce constraints between dynamic components. All constrainers are instances of the Java interface Constrainer. - Attachments

-

Attachments between dynamic components. While technically these are constraints, they are implemented using a different approach. All attachment components are instances of DynamicAttachment.

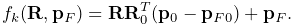

The positions, velocities, and forces associated with all the

dynamic components are denoted by the composite vectors

![]() ,

, ![]() , and

, and ![]() .

In addition, the composite mass matrix is given by

.

In addition, the composite mass matrix is given by

![]() .

Newton’s second law then gives

.

Newton’s second law then gives

| (1.1) |

where the ![]() accounts for various “fictitious” forces.

accounts for various “fictitious” forces.

Each integration step involves solving for

the velocities ![]() at time step

at time step ![]() given the velocities and forces

at step

given the velocities and forces

at step ![]() . One way to do this is to solve the expression

. One way to do this is to solve the expression

| (1.2) |

for ![]() , where

, where ![]() is the step size and

is the step size and

![]() . Given the updated velocities

. Given the updated velocities ![]() , one can

determine

, one can

determine ![]() from

from

| (1.3) |

where ![]() accounts for situations (like rigid bodies) where

accounts for situations (like rigid bodies) where ![]() , and then solve for the updated positions using

, and then solve for the updated positions using

| (1.4) |

(1.2) and (1.4) together comprise a simple symplectic Euler integrator.

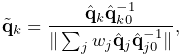

In addition to forces, bilateral and unilateral constraints give rise to

locally linear constraints on ![]() of the form

of the form

| (1.5) |

Bilateral constraints may include rigid body joints, FEM

incompressibility, and point-surface constraints, while unilateral

constraints include contact and joint limits. Constraints give rise

to constraint forces (in the directions ![]() and

and ![]() )

which supplement the forces of (1.1) in order to enforce

the constraint conditions. In addition, for unilateral constraints,

we have a complementarity condition in which

)

which supplement the forces of (1.1) in order to enforce

the constraint conditions. In addition, for unilateral constraints,

we have a complementarity condition in which ![]() implies no

constraint force, and a constraint force implies

implies no

constraint force, and a constraint force implies ![]() . Any

given constraint usually involves only a few dynamic components and so

. Any

given constraint usually involves only a few dynamic components and so

![]() and

and ![]() are generally sparse.

are generally sparse.

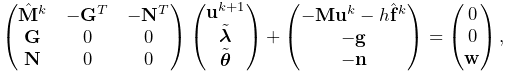

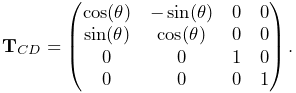

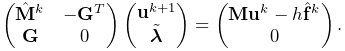

Adding constraints to the velocity solve (1.2) leads to a mixed linear complementarity problem (MLCP) of the form

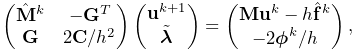

|

|||

| (1.6) |

where ![]() is a slack variable,

is a slack variable, ![]() and

and ![]() give the force

constraint impulses over the time step, and

give the force

constraint impulses over the time step, and ![]() and

and ![]() are

derivative terms defined by

are

derivative terms defined by

| (1.7) |

to account for time variations in ![]() and

and ![]() .

In addition,

.

In addition,

![]() and

and ![]() are

are ![]() and

and ![]() augmented with stiffness

and damping terms terms to accommodate implicit integration, which

is often required for problems involving deformable bodies.

The actual constraint forces

augmented with stiffness

and damping terms terms to accommodate implicit integration, which

is often required for problems involving deformable bodies.

The actual constraint forces ![]() and

and ![]() can be determined

by dividing the impulses by the time step

can be determined

by dividing the impulses by the time step ![]() :

:

| (1.8) |

We note here that ArtiSynth uses a full coordinate formulation, in which the position of each dynamic body is solved using full, or unconstrained, coordinates, with constraint relationships acting to restrict these coordinates. In contrast, some other simulation systems, including OpenSim [7], use reduced coordinates, in which the system dynamics are formulated using a smaller set of coordinates (such as joint angles) that implicitly take the system’s constraints into account. Each methodology has its own advantages. Reduced formulations yield systems with fewer degrees of freedom and no constraint errors. On the other hand, full coordinates make it easier to combine and connect a wide range of components, including rigid bodies and FEM models.

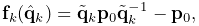

Attachments between components can be implemented by constraining the velocities of the attached components using special constraints of the form

| (1.9) |

where ![]() and

and ![]() denote the velocities of the attached and

non-attached components. The constraint matrix

denote the velocities of the attached and

non-attached components. The constraint matrix ![]() is

sparse, with a non-zero block entry for each master component to

which the attached component is connected. The simplest case involves

attaching a point

is

sparse, with a non-zero block entry for each master component to

which the attached component is connected. The simplest case involves

attaching a point ![]() to another point

to another point ![]() , with the simple velocity relationship

, with the simple velocity relationship

| (1.10) |

That means that ![]() has a single entry of

has a single entry of ![]() (where

(where ![]() is the

is the ![]() identity matrix) in the

identity matrix) in the ![]() -th block column.

Another common case involves connecting a point

-th block column.

Another common case involves connecting a point ![]() to

a rigid frame

to

a rigid frame ![]() . The velocity relationship for this is

. The velocity relationship for this is

| (1.11) |

where ![]() and

and ![]() are the translational and rotational

velocity of the frame and

are the translational and rotational

velocity of the frame and ![]() is the location of the point relative

to the frame’s origin (as seen in world coordinates). The corresponding

is the location of the point relative

to the frame’s origin (as seen in world coordinates). The corresponding

![]() contains a single

contains a single ![]() block entry of the form

block entry of the form

| (1.12) |

in the ![]() block column, where

block column, where

![[l]\equiv\left(\begin{matrix}0&-l_{z}&l_{y}\\

l_{z}&0&-l_{x}\\

-l_{y}&l_{x}&0\end{matrix}\right)](mi/mi1791.png) |

(1.13) |

is a skew-symmetric cross product matrix.

The attachment constraints ![]() could be added directly to

(1.6), but their special form allows us to

explicitly solve for

could be added directly to

(1.6), but their special form allows us to

explicitly solve for ![]() , and hence reduce the size of

(1.6), by factoring out the attached velocities

before solution.

, and hence reduce the size of

(1.6), by factoring out the attached velocities

before solution.

The MLCP (1.6) corresponds to a single step integrator. However, higher order integrators, such as Newmark methods, usually give rise to MLCPs with an equivalent form. Most ArtiSynth integrators use some variation of (1.6) to determine the system velocity at each time step.

To set up (1.6), the MechModel component

hierarchy is traversed and the methods of the different component

types are queried for the required values. Dynamic components (type

DynamicComponent) provide ![]() ,

, ![]() , and

, and ![]() ; force effectors

(ForceEffector) determine

; force effectors

(ForceEffector) determine ![]() and the stiffness/damping

augmentation used to produce

and the stiffness/damping

augmentation used to produce ![]() ; constrainers (Constrainer) supply

; constrainers (Constrainer) supply ![]() ,

, ![]() ,

, ![]() and

and ![]() , and attachments (DynamicAttachment) provide the information needed to factor out

attached velocities.

, and attachments (DynamicAttachment) provide the information needed to factor out

attached velocities.

1.3 Basic packages

The core code of the ArtiSynth project is divided into three main packages, each with a number of sub-packages.

1.3.1 maspack

The packages under maspack contain general computational utilities that are independent of ArtiSynth and could be used in a variety of other contexts. The main packages are:

1.3.2 artisynth.core

The packages under artisynth.core contain the core code for ArtiSynth model components and its GUI infrastructure.

1.3.3 artisynth.demos

These packages contain demonstration models that illustrate ArtiSynth’s modeling capabilities:

1.4 Properties

ArtiSynth components expose properties, which provide a uniform interface for accessing their internal parameters and state. Properties vary from component to component; those for RigidBody include position, orientation, mass, and density, while those for AxialSpring include restLength and material. Properties are particularly useful for automatically creating control panels and probes, as described in Section 5. They are also used for automating component serialization.

Properties are described only briefly in this section; more detailed descriptions are available in the Maspack Reference Manual and the overview paper.

The set of properties defined for a component is fixed for that component’s class; while property values may vary between component instances, their definitions are class-specific. Properties are exported by a class through code contained in the class definition, as described in Section 5.2.

1.4.1 Querying and setting property values

Each property has a unique name that can be used to access its value interactively in the GUI. This can be done either by using a custom control panel (Section 5.1) or by selecting the component and choosing Edit properties ... from the right-click context menu).

Properties can also be accessed in code using their set/get accessor methods. Unless otherwise specified, the names for these are formed by simply prepending set or get to the property’s name. More specifically, a property with the name foo and a value type of Bar will usually have accessor signatures of

1.4.2 Property handles and paths

A property’s name can also be used to obtain a property handle through which its value may be queried or set generically. Property handles are implemented by the class Property and are returned by the component’s getProperty() method. getProperty() takes a property’s name and returns the corresponding handle. For example, components of type Muscle have a property excitation, for which a handle may be obtained using a code fragment such as

Property handles can also be obtained for subcomponents, using a property path that consists of a path to the subcomponent followed by a colon ‘:’ and the property name. For example, to obtain the excitation property for a subcomponent located by axialSprings/lad relative to a MechModel, one could use a call of the form

1.4.3 Composite and inheritable properties

Composite properties are possible, in which a property value is a composite object that in turn has subproperties. A good example of this is the RenderProps class, which is associated with the property renderProps for renderable objects and which itself can have a number of subproperties such as visible, faceStyle, faceColor, lineStyle, lineColor, etc.

Properties can be declared to be inheritable, so that their values can be inherited from the same properties hosted by ancestor components further up the component hierarchy. Inheritable properties require a more elaborate declaration and are associated with a mode which may be either Explicit or Inherited. If a property’s mode is inherited, then its value is obtained from the closest ancestor exposing the same property whose mode is explicit. In Figure (1.1), the property stiffness is explicitly set in components A, C, and E, and inherited in B and D (which inherit from A) and F (which inherits from C).

1.5 Creating an application model

ArtiSynth applications are created by writing and compiling an application model that is a subclass of RootModel. This application-specific root model is then loaded and run by the ArtiSynth program.

The code for the application model should:

-

•

Declare a no-args constructor

-

•

Override the RootModel build() method to construct the application.

ArtiSynth can load a model either using the build method or by reading it from a file:

- Build method

-

ArtiSynth creates an instance of the model using the no-args constructor, assigns it a name (which is either user-specified or the simple name of the class), and then calls the build() method to perform the actual construction.

- Reading from a file

-

ArtiSynth creates an instance of the model using the no-args constructor, and then the model is named and constructed by reading the file.

The no-args constructor should perform whatever initialization is required in both cases, while the build() method takes the place of the file specification. Unless a model is originally created using a file specification (which is very tedious), the first time creation of a model will almost always entail using the build() method.

The general template for application model code looks like this:

Here, the model itself is called MyModel, and is defined in the (hypothetical) package artisynth.models.experimental (placing models in the super package artisynth.models is common practice but not necessary).

Note: The build() method was only introduced in ArtiSynth 3.1. Prior to that, application models were constructed using a constructor taking a String argument supplying the name of the model. This method of model construction still works but is deprecated.

1.5.1 Implementing the build() method

As mentioned above, the build() method is responsible for actual model construction. Many applications are built using a single top-level MechModel. Build methods for these may look like the following:

First, a MechModel is created (with the name "mech" in this example, although any name, or no name, may be given) and added to the list of models in the root model using the addModel() method. Subsequent code then creates and adds the components required by the MechModel, as described in Sections 3, 4 and 6. The build() method also creates and adds to the root model any agents required by the application (controllers, probes, etc.), as described in Section 5.

When constructing a model, there is no fixed order in which components need to be added. For instance, in the above example, addModel(mech) could be called near the end of the build() method rather than at the beginning. The only restriction is that when a component is added to the hierarchy, all other components that it refers to should already have been added to the hierarchy. For instance, an axial spring (Section 3.1) refers to two points. When it is added to the hierarchy, those two points should already be present in the hierarchy.

The build() method supplies a String array as an argument, which can be used to transmit application arguments in a manner analogous to the args argument passed to static main() methods. Build arguments can be specified when a model is loaded directly from a class using Models > Load from class ..., or when the startup model is set to automatically load a model when ArtiSynth is first started (Settings > Startup model). Details are given in the “Loading, Simulating and Saving Models” section of the User Interface Guide.

Build arguments can also be listed directly on the ArtiSynth command line when specifying a model to load using the -model <classname> option. This is done by enclosing the desired arguments within square brackets [ ] immediately following the -model option. So, for example,

> artisynth -model projects.MyModel [ -size 50 ]

would cause the strings "-size" and "50" to be passed to the build() method of MyModel.

1.5.2 Making models visible to ArtiSynth

In order to load an application model into ArtiSynth, the classes associated with its implementation must be made visible to ArtiSynth. This usually involves adding the top-level class folder associated with the application code to the classpath used by ArtiSynth.

The demonstration models referred to in this guide belong to the package artisynth.demos.tutorial and are already visible to ArtiSynth.

In most current ArtiSynth projects, classes are stored in a folder tree separate from the source code, with the top-level class folder named classes, located one level below the project root folder. A typical top-level class folder might be stored in a location like this:

/home/joeuser/artisynthProjects/classes

In the example shown in Section 1.5, the model was created in the package artisynth.models.experimental. Since Java classes are arranged in a folder structure that mirrors package names, with respect to the sample project folder shown above, the model class would be located in

/home/joeuser/artisynthProjects/classes/artisynth/models/experimental

At present there are three ways to make top-level class folders known to ArtiSynth:

- Add projects to your Eclipse launch configuration

-

If you are using the Eclipse IDE, then you can add the project in which are developing your model code to the launch configuration that you use to run ArtiSynth. Other IDEs will presumably provide similar functionality.

- Add the folders to the external classpath

-

You can explicitly add the class folders to ArtiSynth’s external classpath. The easiest way to do this is to select “Settings > External classpath ...” from the Settings menu, which will open an external classpath editor which lists all the classpath entries in a large panel on the left. (When ArtiSynth is first installed, the external classpath has no entries, and so this panel will be blank.) Class folders can then by added via the “Add class folder” button, and the classpath is saved using the Save button.

- Add the folders to your CLASSPATH environment variable

-

If you are running ArtiSynth from the command line, using the artisynth command (or artisynth.bat on Windows), then you can define a CLASSPATH environment variable in your environment and add the needed folders to this.

1.5.3 Loading and running a model

If a model’s classes are visible to ArtiSynth, then it may be loaded into ArtiSynth in several ways:

- Loading from the Model menu

-

If the root model is contained in a package located under artisynth.demos or artisynth.models, then it will appear in the default model menu (Models in the main menu bar) under the submenu All demos or All models.

- Loading by class path

-

A model may also be loaded by choosing “Load from class ...” from the Models menu and specifying its package name and then choosing its root model class. It is also possible to use the -model <classname> command line argument to have a model loaded directly into ArtiSynth when it starts up.

- Loading from a file

-

If a model has been saved to a .art file, it may be loaded from that file by choosing File > Load model ....

These methods are described in detail in the section “Loading and Simulating Models” of the ArtiSynth User Interface Guide.

The demonstration models referred to in this guide should already be present in the model menu and may be loaded from the submenu Models > All demos > tutorial.

Once a model is loaded, it can be simulated, or run. Simulation of the model can then be started, paused, single-stepped, or reset using the play controls (Figure 1.2) located at the upper right of the ArtiSynth window frame. Starting and stopping a simulation is done by clicking play/pause, while reset resets the simulation to time 0. The single-step button advances the simulation by one time step. The stop-all button will also stop the simulation, along with any Jython commands or scripts that are running.

Comprehensive information on exploring and interacting with models is given in the ArtiSynth User Interface Guide.

Chapter 2 Supporting classes

ArtiSynth uses a large number of supporting classes, mostly defined in the super package maspack, for handling mathematical and geometric quantities. Those that are referred to in this manual are summarized in this section.

2.1 Vectors and matrices

Among the most basic classes are those used to implement vectors and matrices, defined in maspack.matrix. All vector classes implement the interface Vector and all matrix classes implement Matrix, which provide a number of standard methods for setting and accessing values and reading and writing from I/O streams.

General sized vectors and matrices are implemented by VectorNd and MatrixNd. These provide all the usual methods for linear algebra operations such as addition, scaling, and multiplication:

As illustrated in the above example, vectors and matrices both provide a toString() method that allows their elements to be formatted using a C-printf style format string. This is useful for providing concise and uniformly formatted output, particularly for diagnostics. The output from the above example is

result= 4.000 12.000 12.000 24.000 20.000

Detailed specifications for the format string are provided in the documentation for NumberFormat.set(String). If either no format string, or the string "%g", is specified, toString() formats all numbers using the full-precision output provided by Double.toString(value).

For computational efficiency, a number of fixed-size vectors and matrices are also provided. The most commonly used are those defined for three dimensions, including Vector3d and Matrix3d:

2.2 Rotations and transformations

maspack.matrix contains a number classes that implement rotation matrices, rigid transforms, and affine transforms.

Rotations (Section A.1) are commonly described using a RotationMatrix3d, which implements a rotation matrix and contains numerous methods for setting rotation values and transforming other quantities. Some of the more commonly used methods are:

Rotations can also be described by AxisAngle, which characterizes a rotation as a single rotation about a specific axis.

Rigid transforms (Section A.2) are used by ArtiSynth to describe a rigid body’s pose, as well as its relative position and orientation with respect to other bodies and coordinate frames. They are implemented by RigidTransform3d, which exposes its rotational and translational components directly through the fields R (a RotationMatrix3d) and p (a Vector3d). Rotational and translational values can be set and accessed directly through these fields. In addition, RigidTransform3d provides numerous methods, some of the more commonly used of which include:

Affine transforms (Section A.3) are used by ArtiSynth to effect scaling and shearing transformations on components. They are implemented by AffineTransform3d.

Rigid transformations are actually a specialized form of affine transformation in which the basic transform matrix equals a rotation. RigidTransform3d and AffineTransform3d hence both derive from the same base class AffineTransform3dBase.

2.3 Points and Vectors

The rotations and transforms described above can be used to transform both vectors and points in space.

Vectors are most commonly implemented using Vector3d, while points can be implemented using the subclass Point3d. The only difference between Vector3d and Point3d is that the former ignores the translational component of rigid and affine transforms; i.e., as described in Sections A.2 and A.3, a vector v has an implied homogeneous representation of

| (2.1) |

while the representation for a point p is

| (2.2) |

Both classes provide a number of methods for applying rotational and affine transforms. Those used for rotations are

where R is a rotation matrix and v1 is a vector (or a point in the case of Point3d).

The methods for applying rigid or affine transforms include:

where X is a rigid or affine transform. As described above, in the case of Vector3d, these methods ignore the translational part of the transform and apply only the matrix component (R for a RigidTransform3d and A for an AffineTransform3d). In particular, that means that for a RigidTransform3d given by X and a Vector3d given by v, the method calls

produce the same result.

2.4 Spatial vectors and inertias

The velocities, forces and inertias associated with 3D coordinate frames and rigid bodies are represented using the 6 DOF spatial quantities described in Sections A.5 and A.6. These are implemented by classes in the package maspack.spatialmotion.

Spatial velocities (or twists) are implemented by Twist, which exposes its translational and angular velocity components through the publicly accessible fields v and w, while spatial forces (or wrenches) are implemented by Wrench, which exposes its translational force and moment components through the publicly accessible fields f and m.

Both Twist and Wrench contain methods for algebraic operations such as addition and scaling. They also contain transform() methods for applying rotational and rigid transforms. The rotation methods simply transform each component by the supplied rotation matrix. The rigid transform methods, on the other hand, assume that the supplied argument represents a transform between two frames fixed within a rigid body, and transform the twist or wrench accordingly, using either (A.27) or (A.29).

The spatial inertia for a rigid body is implemented by SpatialInertia, which contains a number of methods for setting its value given various mass, center of mass, and inertia values, and querying the values of its components. It also contains methods for scaling and adding, transforming between coordinate systems, inversion, and multiplying by spatial vectors.

2.5 Meshes

ArtiSynth makes extensive use of 3D meshes, which are defined in maspack.geometry. They are used for a variety of purposes, including visualization, collision detection, and computing physical properties (such as inertia or stiffness variation within a finite element model).

A mesh is essentially a collection of vertices (i.e., points) that are topologically connected in some way. All meshes extend the abstract base class MeshBase, which supports the vertex definitions, while subclasses provide the topology.

Through MeshBase, all meshes provide methods for adding and accessing vertices. Some of these include:

Vertices are implemented by Vertex3d, which defines the position of the vertex (returned by the method getPosition()), and also contains support for topological connections. In addition, each vertex maintains an index, obtainable via getIndex(), that equals the index of its location within the mesh’s vertex list. This makes it easy to set up parallel array structures for augmenting mesh vertex properties.

Mesh subclasses currently include:

- PolygonalMesh

-

Implements a 2D surface mesh containing faces implemented using half-edges.

- PolylineMesh

-

Implements a mesh consisting of connected line-segments (polylines).

- PointMesh

-

Implements a point cloud with no topological connectivity.

PolygonalMesh is used quite extensively and provides a number of methods for implementing faces, including:

The class Face implements a face as a counter-clockwise arrangement of vertices linked together by half-edges (class HalfEdge). Face also supplies a face’s (outward facing) normal via getNormal().

Some mesh uses within ArtiSynth, such as collision detection, require a triangular mesh; i.e., one where all faces have three vertices. The method isTriangular() can be used to check for this. Meshes that are not triangular can be made triangular using triangulate().

2.5.1 Mesh creation

Meshes are most commonly created using either one of the factory methods supplied by MeshFactory, or by reading a definition from a file (Section 2.5.5). However, it is possible to create a mesh by direct construction. For example, the following code fragment creates a simple closed tetrahedral surface:

Some of the more commonly used factory methods for creating polyhedral meshes include:

Each factory method creates a mesh in some standard coordinate

frame. After creation, the mesh can be transformed using the

transform(X) method, where X is either a rigid transform (

RigidTransform3d) or a more general affine

transform (AffineTransform3d).

For example, to create a rotated box centered on ![]() ,

one could do:

,

one could do:

One can also scale a mesh using scale(s), where s is a single scale factor, or scale(sx,sy,sz), where sx, sy, and sz are separate scale factors for the x, y and z axes. This provides a useful way to create an ellipsoid:

MeshFactory can also be used to create new meshes by performing Boolean operations on existing ones:

2.5.2 Setting normals, colors, and textures

Meshes provide support for adding normal, color, and texture information, with the exact interpretation of these quantities depending upon the particular mesh subclass. Most commonly this information is used simply for rendering, but in some cases normal information might also be used for physical simulation.

For polygonal meshes, the normal information described here is used only for smooth shading. When flat shading is requested, normals are determined directly from the faces themselves.

Normal information can be set and queried using the following methods:

The method setNormals() takes two arguments: a set of normal vectors (nrmls), along with a set of index values (indices) that map these normals onto the vertices of each of the mesh’s geometric features. Often, there will be one unique normal per vertex, in which case nrmls will have a size equal to the number of vertices, but this is not always the case, as described below. Features for the different mesh subclasses are: faces for PolygonalMesh, polylines for PolylineMesh, and vertices for PointMesh. If indices is specified as null, then normals is assumed to have a size equal to the number of vertices, and an appropriate index set is created automatically using createVertexIndices() (described below). Otherwise, indices should have a size of equal to the number of features times the number of vertices per feature. For example, consider a PolygonalMesh consisting of two triangles formed from vertex indices (0, 1, 2) and (2, 1, 3), respectively. If normals are specified and there is one unique normal per vertex, then the normal indices are likely to be

[ 0 1 2 2 1 3 ]

As mentioned above, sometimes there may be more than one normal per vertex. This happens in cases when the same vertex uses different normals for different faces. In such situations, the size of the nrmls argument will exceed the number of vertices.

The method setNormals() makes internal copies of the specified normal and index information, and this information can be later read back using getNormals() and getNormalIndices(). The number of normals can be queried using numNormals(), and individual normals can be queried or set using getNormal(idx) and setNormal(idx,nrml). All normals and indices can be explicitly cleared using clearNormals().

Color and texture information can be set using analogous methods. For colors, we have

When specified as float[], colors are given as RGB or

RGBA values, in the range ![]() , with array lengths of 3 and 4,

respectively. The colors returned by

getColors() are always RGBA

values.

, with array lengths of 3 and 4,

respectively. The colors returned by

getColors() are always RGBA

values.

With colors, there may often be fewer colors than the number of vertices. For instance, we may have only two colors, indexed by 0 and 1, and want to use these to alternately color the mesh faces. Using the two-triangle example above, the color indices might then look like this:

[ 0 0 0 1 1 1 ]

Finally, for texture coordinates, we have

When specifying indices using setNormals, setColors, or setTextureCoords, it is common to use the same index set as that which associates vertices with features. For convenience, this index set can be created automatically using

Alternatively, we may sometimes want to create a index set that assigns the same attribute to each feature vertex. If there is one attribute per feature, the resulting index set is called a feature index set, and can be created using

If we have a mesh with three triangles and one color per triangle, the resulting feature index set would be

[ 0 0 0 1 1 1 2 2 2 ]

Note: when a mesh is modified by the addition of new features (such as faces for PolygonalMesh), all normal, color and texture information is cleared by default (with normal information being automatically recomputed on demand if automatic normal creation is enabled; see Section 2.5.3). When a mesh is modified by the removal of features, the index sets for normals, colors and textures are adjusted to account for the removal.

For colors, it is possible to request that a mesh explicitly maintain colors for either its vertices or features (Section 2.5.4). When this is done, colors will persist when vertices or features are added or removed, with default colors being automatically created as necessary.

Once normals, colors, or textures have been set, one may want to know which of these attributes are associated with the vertices of a specific feature. To know this, it is necessary to find that feature’s offset into the attribute’s index set. This offset information can be found using the array returned by

For example, the three normals associated with a triangle at index ti can be obtained using

Alternatively, one may use the convenience methods

which return the attribute values for the ![]() -th vertex of

the feature indexed by fidx.

-th vertex of

the feature indexed by fidx.

In general, the various get methods return references to internal storage information and so should not be modified. However, specific values within the lists returned by getNormals(), getColors(), or getTextureCoords() may be modified by the application. This may be necessary when attribute information changes as the simulation proceeds. Alternatively, one may use methods such as setNormal(idx,nrml) setColor(idx,color), or setTextureCoords(idx,coords).

Also, in some situations, particularly with colors and textures, it may be desirable to not have color or texture information defined for certain features. In such cases, the corresponding index information can be specified as -1, and the getNormal(), getColor() and getTexture() methods will return null for the features in question.

2.5.3 Automatic creation of normals and hard edges

For some mesh subclasses, if normals are not explicitly set, they are computed automatically whenever getNormals() or getNormalIndices() is called. Whether or not this is true for a particular mesh can be queried by the method

Setting normals explicitly, using a call to setNormals(nrmls,indices), will overwrite any existing normal information, automatically computed or otherwise. The method

will return true if normals have been explicitly set, and false if they have been automatically computed or if there is currently no normal information. To explicitly remove normals from a mesh which has automatic normal generation, one may call setNormals() with the nrmls argument set to null.

More detailed control over how normals are automatically created may be available for specific mesh subclasses. For example, PolygonalMesh allows normals to be created with multiple normals per vertex, for vertices that are associated with either open or hard edges. This ability can be controlled using the methods

Having multiple normals means that even with smooth shading, open or hard edges will still appear sharp. To make an edge hard within a PolygonalMesh, one may use the methods

which control the hardness of edges between individual vertices, specified either directly or using their indices.

2.5.4 Vertex and feature coloring

The method setColors() makes it possible to assign any desired coloring scheme to a mesh. However, it does require that the user explicitly reset the color information whenever new features are added.

For convenience, an application can also request that a mesh explicitly maintain colors for either its vertices or features. These colors will then be maintained when vertices or features are added or removed, with default colors being automatically created as necessary.

Vertex-based coloring can be requested with the method

This will create a separate (default) color for each of the mesh’s vertices, and set the color indices to be equal to the vertex indices, which is equivalent to the call

where colors contains a default color for each vertex. However, once vertex coloring is enabled, the color and index sets will be updated whenever vertices or features are added or removed. Meanwhile, applications can query or set the colors for any vertex using getColor(idx), or any of the various setColor methods. Whether or not vertex coloring is enabled can be queried using

Once vertex coloring is established, the application will typically want to set the colors for all vertices, perhaps using a code fragment like this:

Similarly, feature-based coloring can be requested using the method

This will create a separate (default) color for each of the mesh’s features (faces for PolygonalMesh, polylines for PolylineMesh, etc.), and set the color indices to equal the feature index set, which is equivalent to the call

where colors contains a default color for each feature. Applications can query or set the colors for any vertex using getColor(idx), or any of the various setColor methods. Whether or not feature coloring is enabled can be queried using

2.5.5 Reading and writing mesh files

PolygonalMesh, PolylineMesh, and PointMesh all provide constructors that allow them to be created from a definition file, with the file format being inferred from the file name suffix:

| Suffix | Format | PolygonalMesh | PolylineMesh | PointMesh |

|---|---|---|---|---|

| .obj | Alias Wavefront | X | X | X |

| .ply | Polygon file format | X | X | |

| .stl | STereoLithography | X | ||

| .gts | GNU triangulated surface | X | ||

| .off | Object file format | X | ||

| .vtk | VTK ascii format | X | ||

| .vtp | VTK XML format | X | X |

The currently supported file formats, and their applicability to the different mesh types, are given in Table 2.1. For example, a PolygonalMesh can be read from either an Alias Wavefront .obj file or an .stl file, as show in the following example:

The file-based mesh constructors may throw an I/O exception if an I/O error occurs or if the indicated format does not support the mesh type. This exception must either be caught, as in the example above, or thrown out of the calling routine.

In addition to file-based constructors, all mesh types implement read and write methods that allow a mesh to be read from or written to a file, with the file format again inferred from the file name suffix:

For the latter methods, the argument zeroIndexed specifies zero-based vertex indexing in the case of Alias Wavefront .obj files, while fmtStr is a C-style format string specifying the precision and style with which the vertex coordinates should be written. (In the former methods, zero-based indexing is false and vertices are written using full precision.)

As an example, the following code fragment writes a mesh as an .stl file:

Sometimes, more explicit control is needed when reading or writing a mesh from/to a given file format. The constructors and read/write methods described above make use of a specific set of reader and writer classes located in the package maspack.geometry.io. These can be used directly to provide more explicit read/write control. The readers and writers (if implemented) associated with the different formats are given in Table 2.2.

| Suffix | Format | Reader class | Writer class |

|---|---|---|---|

| .obj | Alias Wavefront | WavefrontReader | WavefrontWriter |

| .ply | Polygon file format | PlyReader | PlyWriter |

| .stl | STereoLithography | StlReader | StlWriter |

| .gts | GNU triangulated surface | GtsReader | GtsWriter |

| .off | Object file format | OffReader | OffWriter |

| .vtk | VTK ascii format | VtkAsciiReader | |

| .vtp | VTK XML format | VtkXmlReader |

The general usage pattern for these classes is to construct the desired reader or writer with a path to the desired file, and then call readMesh() or writeMesh() as appropriate:

Both readMesh() and writeMesh() may throw I/O exceptions, which must be either caught, as in the example above, or thrown out of the calling routine.

For convenience, one can also use the classes GenericMeshReader or GenericMeshWriter, which internally create an appropriate reader or writer based on the file extension. This enables the writing of code that does not depend on the file format:

Here, fileName can refer to a mesh of any format supported by GenericMeshReader. Note that the mesh returned by readMesh() is explicitly cast to PolygonalMesh. This is because readMesh() returns the superclass MeshBase, since the default mesh created for some file formats may be different from PolygonalMesh.

2.5.6 Reading and writing normal and texture information

When writing a mesh out to a file, normal and texture information are also written if they have been explicitly set and the file format supports it. In addition, by default, automatically generated normal information will also be written if it relies on information (such as hard edges) that can’t be reconstructed from the stored file information.

Whether or not normal information will be written is returned by the method

This will always return true if any of the conditions described above have been met. So for example, if a PolygonalMesh contains hard edges, and multiple automatic normals are enabled (i.e., getMultipleAutoNormals() returns true), then getWriteNormals() will return true.

Default normal writing behavior can be overridden within the MeshWriter classes using the following methods:

where enable should be one of the following values:

- 0

-

normals will never be written;

- 1

-

normals will always be written;

- -1

-

normals will written according to the default behavior described above.

When reading a PolygonalMesh from a file, if the file contains normal information with multiple normals per vertex that suggests the existence of hard edges, then the corresponding edges are set to be hard within the mesh.

2.5.7 Constructive solid geometry

ArtiSynth contains primitives for performing constructive solid geometry (CSG) operations on volumes bounded by triangular meshes. The class that performs these operations is maspack.collision.SurfaceMeshIntersector, and it works by robustly determining the intersection contour(s) between a pair of meshes, and then using these to compute the triangles that need to be added or removed to produce the necessary CSG surface.

The CSG operations include union, intersection, and difference, and are implemented by the following methods of SurfaceMeshIntersector:

Each takes two PolyhedralMesh objects, mesh0 and mesh1, and creates and returns another PolyhedralMesh which represents the boundary surface of the requested operation. If the result of the operation is null, the returned mesh will be empty.

The example below uses findUnion to create a dumbbell shaped mesh from two balls and a cylinder:

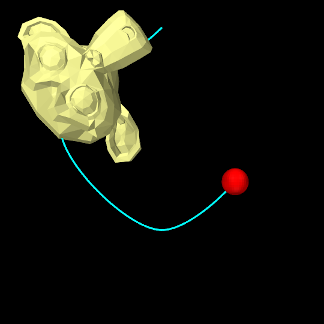

The balls and cylinder are created using the MeshFactory methods createIcosahedralSphere() and createCylinder(), where the latter takes arguments ns, nr, and nh giving the number of slices along the circumference, end-cap radius, and length. The final resulting mesh is shown in Figure 2.1.

2.6 Reading source relative files

ArtiSynth applications frequently need to read in various kinds of data files, including mesh files (as discussed in Section 2.5.5), FEM mesh geometry (Section 6.2.2), probe data (Section 5.4.4), and custom application data.

Often these data files do not reside in an absolute location but instead in a location relative to the application’s class or source files. For example, it is common for applications to store geometric data in a subdirectory "geometry" located beneath the source directory. In order to access such files in a robust way, and ensure that the code does not break when the source tree is moved, it is useful to determine the application’s source (or class) directory at run time. ArtiSynth supplies several ways to conveniently handle this situation. First, the RootModel itself supplies the following methods:

The first method returns the path to the source directory of the root model, while the second returns the path to a file specified relative to the root model source directory. If the root model source directory cannot be found (see discussion at the end of this section) both methods return null. As a specific usage example, assume that we have an application model whose build() method needs to load in a mesh torus.obj from a subdirectory meshes located beneath the source directory. This could be done as follows:

A more general path finding utility is provided by maspack.util.PathFinder, which provides several static methods for locating source and class directories:

The “find” methods return a string path to the indicated class or source directory, while the “relative path” methods locate the class or source directory and append the additional path relpath. For all of these, the class is determined from classObj, either directly (if it is an instance of Class), by name (if it is a String), or otherwise by calling classObj.getClass(). When identifying a package by name, the name should be either a fully qualified class name, or a simple name that can be located with respect to the packages obtained via Package.getPackages(). For example, if we have a class whose fully qualified name is artisynth.models.test.Foo, then the following calls should all return the same result:

If the source directory for Foo happens to be /home/projects/src/artisynth/models/test, then

will return /home/projects/src/artisynth/models/test/geometry/mesh.obj.

When calling PathFinder methods from within the relevant class, one can specify this as the classObj argument.

With respect to the above example locating the file "meshes/torus.obj", the call to the root model method getSourceRelativePath() could be replaced with

Since this is assumed to be called from the root model’s build method, the “class” can be indicated by simply passing this to getSourceRelativePath().

As an alternative to placing data files in the source directory, one could place them in the class directory, and then use findClassDir() and getClassRelativePath(). If the data files were originally defined in the source directory, it will be necessary to copy them to the class directory. Some Java IDEs will perform this automatically.

The PathFinder methods work by climbing the class’s resource hierarchy. Source directories are assumed to be located relative to the parent of the root class directory, via one of the paths specified by getSourceRootPaths(). By default, this list includes "src", "source", and "bin". Additional paths can be added using addSourceRootPath(path), or the entire list can be set using setSourceRootPaths(paths).

At preset, source directories will not be found if the reference class is contained in a jar file.

2.7 Reading and caching remote files

ArtiSynth applications often require the use of large data files to specify items such as FEM mesh geometry, surface mesh geometry, or medical imaging data. The size of these files may make it inconvenient to store them in any version control system that is used to store the application source code. As an alternative, ArtiSynth provides a file manager utility that allows such files to be stored on a separate server, and then downloaded on-demand and cached locally. To use this, one starts by creating an instance of a FileManager, using the constructor

where downloadPath is a path to the local directory where the downloaded file should be placed, and remoteSourceName is a URI indicating the remote server location of the files. After the file manager has been created, it can be used to fetch remote files and cache them locally, using various get methods:

Both of these look for the file destName specified relative to the local directory, and return a File handle for it if it is present. Otherwise, they attempt to download the file from the remote source location, place it in the local directory, and return a File handle for it. The location of the remote file is given relative to the remote source URI by destName for the first method and sourceName for the second.

A simple example of using a file manager within a RootModel build() method is given by the following fragment:

Here, a file manager is created that uses a local directory "geometry", located relative to the RootModel source directory (see Section 2.6), and looks for missing files relative to the URI

http://myserver.org/artisynth/data/geometry

The get() method is then used to obtain the file "tibia.obj" from the local directory. If it is not already present, it is downloaded from the remote location.

The FileManager contains other features and functionality, and one should consult its API documentation for more information.

Chapter 3 Mechanical Models I

This section details how to build basic multibody-type mechanical models consisting of particles, springs, rigid bodies, joints, and other constraints.

3.1 Springs and particles

The most basic type of mechanical model consists simply of particles connected together by axial springs. Particles are implemented by the class Particle, which is a dynamic component containing a three-dimensional position state, a corresponding velocity state, and a mass. It is an instance of the more general base class Point, which is used to also implement spatial points such as markers which do not have a mass.

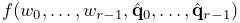

3.1.1 Axial springs and materials

An axial spring is a simple spring that connects two points and is

implemented by the class

AxialSpring. This is a force effector component that exerts equal and opposite forces on the

two points, along the line separating them, with a magnitude ![]() that

is a function

that

is a function ![]() of the distance

of the distance ![]() between the points,

and the distance derivative

between the points,

and the distance derivative ![]() .

.

Each axial spring is associated with an axial material,

implemented by a subclass of

AxialMaterial, that specifies

the function ![]() . The most basic type of axial material is

a LinearAxialMaterial, which

determines

. The most basic type of axial material is

a LinearAxialMaterial, which

determines ![]() according to the linear relationship

according to the linear relationship

| (3.1) |

where ![]() is the rest length and

is the rest length and ![]() and

and ![]() are the stiffness and

damping terms. Both

are the stiffness and

damping terms. Both ![]() and

and ![]() are properties of the material, while

are properties of the material, while

![]() is a property of the spring.

is a property of the spring.

Axial springs are assigned a linear axial material by default. More complex, nonlinear axial materials may be defined in the package artisynth.core.materials. Setting or querying a spring’s material may be done with the methods setMaterial() and getMaterial().

3.1.2 Example: a simple particle-spring model

An complete application model that implements a simple particle-spring model is given below.

Line 1 of the source defines the package in which the model class will reside, in this case artisynth.demos.tutorial. Lines 3-8 import definitions for other classes that will be used.

The model application class is named ParticleSpring and declared to extend RootModel (line 13), and the build() method definition begins at line 15. (A no-args constructor is also needed, but because no other constructors are defined, the compiler creates one automatically.)

To begin, the build() method creates a MechModel named "mech", and then adds it to the models list of the root model using the addModel() method (lines 18-19). Next, two particles, p1 and p2, are created, with masses equal to 2 and initial positions at 0, 0, 0, and 1, 0, 0, respectively (lines 22-23). Then an axial spring is created, with end points set to p1 and p2, and assigned a linear material with a stiffness and damping of 20 and 10 (lines 24-27). Finally, after the particles and the spring are created, they are added to the particles and axialSprings lists of the MechModel using the methods addParticle() and addAxialSpring() (lines 30-32).

At this point in the code, both particles are defined to be

dynamically controlled, so that running the simulation would cause

both to fall under the MechModel’s default gravity acceleration

of ![]() . However, for this example, we want the first

particle to remain fixed in place, so we set it to be non-dynamic (line 34), meaning that the physical simulation will not

update its position in response to forces (Section

3.1.3).

. However, for this example, we want the first

particle to remain fixed in place, so we set it to be non-dynamic (line 34), meaning that the physical simulation will not

update its position in response to forces (Section

3.1.3).

The remaining calls control aspects of how the model is graphically rendered. setBounds() (line 37) increases the model’s “bounding box” so that by default it will occupy a larger part of the viewer frustum. The convenience method RenderProps.setSphericalPoints() is used to set points p1 and p2 to render as solid red spheres with a radius of 0.06, while RenderProps.setCylindricalLines() is used to set spring to render as a solid blue cylinder with a radius of 0.02. More details about setting render properties are given in Section 4.3.

3.1.3 Dynamic, parametric, and attached components

By default, a dynamic component is advanced through time in response to the forces applied to it. However, it is also possible to set a dynamic component’s dynamic property to false, so that it does not respond to force inputs. As shown in the example above, this can be done using the method setDynamic():

comp.setDynamic (false);

The method isDynamic() can be used to query the dynamic property.

Dynamic components can also be attached to other dynamic components (as mentioned in Section 1.2) so that their positions and velocities are controlled by the master components that they are attached to. To attach a dynamic component, one creates an AttachmentComponent specifying the attachment connection and adds it to the MechModel, as described in Section 3.8. The method isAttached() can be used to determine if a component is attached, and if it is, getAttachment() can be used to find the corresponding AttachmentComponent.

Overall, a dynamic component can be in one of three states:

- active

-

Component is dynamic and unattached. The method isActive() returns true. The component will move in response to forces.

- parametric

-

Component is not dynamic, and is unattached. The method isParametric() returns true. The component will either remain fixed, or will move around in response to external inputs specifying the component’s position and/or velocity. One way to supply such inputs is to use controllers or input probes, as described in Section 5.

- attached

-

Component is attached. The method isAttached() returns true. The component will move so as to follow the other master component(s) to which it is attached.

3.1.4 Custom axial materials

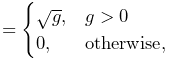

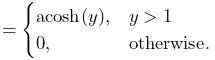

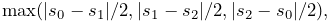

Application authors may create their own axial materials by subclassing AxialMaterial and overriding the functions

where excitation is an additional excitation signal ![]() , which

is used to implement active springs and which in particular is used to

implement axial muscles (Section 4.5), for

which

, which

is used to implement active springs and which in particular is used to

implement axial muscles (Section 4.5), for

which ![]() is usually in the range

is usually in the range ![]() .

.

The first three methods should return the values of

| (3.2) |

respectively, while the last method should return true if

![]() ; i.e., if it is

always equals to 0.

; i.e., if it is

always equals to 0.

3.1.5 Damping parameters

Mechanical models usually contain damping forces in addition to spring-type restorative forces. Damping generates forces that reduce dynamic component velocities, and is usually the major source of energy dissipation in the model. Damping forces can be generated by the spring components themselves, as described above.

A general damping can be set for all particles by setting the MechModel’s pointDamping property. This causes a force

| (3.3) |

to be applied to all particles, where ![]() is the value of the pointDamping and

is the value of the pointDamping and ![]() is the particle’s velocity.

is the particle’s velocity.

pointDamping can be set and queried using the MechModel methods

In general, whenever a component has a property propX, that property can be set and queried in code using methods of the form

setPropX (T d); T getPropX();where T is the type associated with the property.

pointDamping can also be set for particles individually. This property is inherited (Section 1.4.3), so that if not set explicitly, it inherits the nearest explicitly set value in an ancestor component.

3.2 Rigid bodies

Rigid bodies are implemented in ArtiSynth by the class RigidBody, which is a dynamic component containing a six-dimensional position and orientation state, a corresponding velocity state, an inertia, and an optional surface mesh.

A rigid body is associated with its own 3D spatial coordinate frame, and is a subclass of the more general Frame component. The combined position and orientation of this frame with respect to world coordinates defines the body’s pose, and the associated 6 degrees of freedom describe its “position” state.

3.2.1 Frame markers

ArtiSynth makes extensive use of markers, which are (massless) points attached to dynamic components in the model. Markers are used for graphical display, implementing attachments, and transmitting forces back onto the underlying dynamic components.

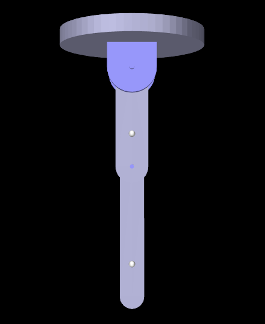

A frame marker is a marker that can be attached to a Frame, and most commonly to a RigidBody (Figure 3.2). They are frequently used to provide the anchor points for attaching springs and, more generally, applying forces to the body.

Frame markers are implemented by the class FrameMarker, which is a subclass of Point. The methods

get and set the marker’s location ![]() with respect to the frame’s

coordinate system. When a 3D force

with respect to the frame’s

coordinate system. When a 3D force ![]() is applied to the marker, it

generates a spatial force

is applied to the marker, it

generates a spatial force ![]() (Section

A.5) on the frame given by

(Section

A.5) on the frame given by

| (3.4) |

Frame markers can be created using a variety of constructors, including

where FrameMarker() creates an empty marker, FrameMarker(name) creates an empty marker with a name, and FrameMarker(frame,loc) creates an unnamed marker attached to frame at the location loc with respect to the frame’s coordinates. Once created, a marker’s frame can be set and queried with

A frame marker can be added to a MechModel with the MechModel methods

where addFrameMarker(mkr,frame,loc) also sets the frame and the marker’s location with respect to it.

MechModel also supplies convenience methods to create a marker, attach it to a frame, and add it to the model:

Both methods return the created marker. The first, addFrameMarker(frame,loc), places it at the location loc with respect to the frame, while addFrameMarkerWorld(frame,pos) places it at pos with respect to world coordinates.

3.2.2 Example: a simple rigid body-spring model

A simple rigid body-spring model is defined in

artisynth.demos.tutorial.RigidBodySpring

This differs from ParticleSpring only in the build() method, which is listed below:

The differences from ParticleSpring begin

at line 9. Instead of creating a second particle, a rigid body is

created using the factory method

RigidBody.createBox(), which

takes x, y, z widths and a (uniform) density and creates a box-shaped

rigid body complete with surface mesh and appropriate mass and

inertia. As the box is initially centered at the origin, moving it

elsewhere requires setting the body’s pose, which is done using setPose(). The RigidTransform3d passed to setPose() is

created using a three-argument constructor that generates a

translation-only transform. Next, starting at line 14, a FrameMarker is created for a location ![]() relative to the

rigid body, and attached to the body using its setFrame()

method.

relative to the

rigid body, and attached to the body using its setFrame()

method.

The remainder of build() is the same as for ParticleSpring, except that the spring is attached to the frame marker instead of a second particle.

3.2.3 Creating rigid bodies

As illustrated above, rigid bodies can be created using factory methods supplied by RigidBody. Some of these include:

The bodies do not need to be named; if no name is desired, then name and can be specified as null.