ArtiSynth User Interface Guide

Last update: February, 2023

Contents

- 1 Introduction

- 2 Loading, Simulating and Saving Models

-

3 The Viewer

- 3.1 Viewer Toolbar

- 3.2 Viewpoint control

- 3.3 Setting aligned axis viewpoints

- 3.4 Adding additional viewers

- 3.5 World coordinate axes

- 3.6 Orthographic vs. perspective projection

- 3.7 Viewer grid

- 3.8 Clipping planes

- 3.9 Indicating 3D positions with the mouse

- 3.10 Viewer properties

- 3.11 Mouse Bindings

- 3.12 Keyboard shortcuts

- 4 Component Navigation and Selection

- 5 Model Manipulation

- 6 Editing Properties

- 7 The Timeline

- 8 Saving and Loading Probes

- 9 Adding and Editing Numeric Probes

- 10 Point Tracing

- 11 Settings and Preferences

- 12 Jython Interaction and Scripting

- 13 Customizing the Model and Script Menus

- 14 Making Movies

- 15 Control Panels

- 16 Component Editing

1 Introduction

This manual describes the ArtiSynth user interface (UI), and how it can be used to edit models and interactively monitor and control their simulation.

1.1 User configuration folder

By default, ArtiSynth tries to store user-specific settings and configuration information in various files located under the user configuration folder, the path to which is given by

<HOME>/ArtiSynthConfig

where <HOME> is the user’s home folder. Default instances of these files will be created when they are first accessed or recreated if they are later found to be corrupt or missing.

2 Loading, Simulating and Saving Models

The first thing an ArtiSynth user is likely to want is to load a demonstration model, and explore and simulate it.

An ArtiSynth model is defined by a Java class which is a subclass of the ArtiSynth RootModel component. This class builds the model, serves as the root container for all its components, and implements the advance() method which allows the model to be simulated.

A number of predefined demonstration models come bundled with the ArtiSynth distribution and are declared within subpackages of artisynth.demos. These are generally simple models that illustrate particular simulation capabilities. More complex anatomical models, including those used in various research projects and mostly focused on head and neck anatomy, are available in the separate project artisynth_models, which must be downloaded separately (see www.artisynth.org/models for instructions). These anatomical models are declared within subpackages of artisynth.models.

To run user-defined models defined within Java packages that are outside of the project artisynth_core, it is necessary to arrange for their classpaths to be visible to the ArtiSynth application. One way to do this is to add the classpaths to the ArtiSynth external classpath, as described in Section 2.9. If one is using an integrated development environment (IDE) for Java compilation and execution, this linking can also be done within the IDE. More detailed information on this topic is given in the section “Making external models visible to ArtiSynth” of the ArtiSynth Installation Guide.

2.1 Loading from the model menu

Some models can be loaded directly using the Models menu located in the ArtiSynth menu bar (Figure 1). By default, the upper part of this menu contains a number of submenus:

| Demos | - all models listed in the file demoModels.txt (described below); |

|---|---|

| All Demos | - every model found in artisynth.demos or its subpackages, arranged hierarchically. |

In addition, if artisynth_models has also been installed, or if ArtiSynth otherwise detects the presence of the superpackage artisynth.models, then the Models menu will also contain:

| Models | - all models listed in the file mainModels.txt (described below); |

|---|---|

| All Models | - every model found in artisynth.models or its subpackages, arranged hierarchically. |

Each submenu expands out to identify a set of models. Selecting one of the models will cause it to be loaded into ArtiSynth and displayed in the viewer. Hovering over one of the entries will display the full classname of the associated RootModel. The files demoModels.txt and mainModels.txt are located in the settings subfolder of the user configuration folder (Section 1.1); default instances of these are created the first time ArtiSynth is run, and they can later be modified by the user.

The lower part of the model menu, beneath the separator, contains entries for reloading recent models (Section 2.4), loading a model from an explicitly specified class (Section 2.2), and customizing the upper part of the the model menu (Section 13).

Model menu customization is is needed to create menu entries for root models not defined within (or beneath) the packages artisynth.demos or artisynth.models.

2.2 Loading directly by class

As mentioned above, models are defined by subclasses of RootModel. A model may therefore be loaded into ArtiSynth by directly specifying the class that defines its RootModel. To do this, choose “Load from class ...” from the lower part of the model menu, which will bring up a model selection dialog as shown in Figure 2.

Users should specify the name of the package containing the model in the “Model package” field at the top. Using the <TAB> character in this field will invoke auto-completion based on currently know packages, while repeated use of either <TAB> or the up/down arrows will scroll through known packages. Package entry is completed using the <ENTER> key, and any models that appear in that package (but not its subpackages) will then be displayed in the “Model class” panel below it. The user can then select the desired model by clicking on it. In Figure 2, the model defined by the class artisynth.demos.mech.LaymanDemo has been selected.

If the model requires command-line style arguments to its build() method (as described in the section “Implementing the build() method” of the ArtiSynth Modeling Guide), these can be entered in the “Build args” field near the dialog bottom. Arguments should be separated by white space, with those containing white space placed between double quotes ‘"’. The last field, “Waypoints file”, can optionally be used to specify a file containing simulation way points (Section 7.3.1). As with all externally loaded waypoint data, the waypoints must match the current model structure.

When all desired settings have been made, the model can be loaded by clicking the Load button.

2.3 Loading from a file

Finally, it is possible to load a model from a file. Selecting “Load model ...” from the File menu will bring up a File browser that lets you select and load a model from an ArtiSynth model file. ArtiSynth model files are text-based documents that contain a hierarchical description of all the model’s components, and are typically identified by the extension .art.

When loading a model from a .art file, it is necessary to have all classes associated with that model in the current Java classpath. This can be an issue when loading files generated by other users using application-specific Java code. Two possible solutions to this are: (a) bundling the application-specific code into a .jar file and adding it to the external classpath (Section 2.9), or (b) making sure that the file was saved using only artisynth_core components, as described in Section 2.8.

2.4 Loading recent models

After a model has been loaded by any of the methods described above, it can be reloaded by selecting “Reload model” from the lower part of the model menu. Models which have been recently loaded can be reloaded by selecting “Load recent” from the Models menu.

2.5 Setting a startup model

When working repeatedly with a specific model, it can be useful to set that model to automatically load when ArtiSynth starts up. This can be done by setting the startup model, by choosing “Startup model ...” from the Settings menu. This will open a startup model dialog as shown in Figure 3.

The model to load can be specified either by class or by file. To specify the model by class, one uses the “Model package”, “Model class” and “Build args” fields to choose the model class and optional build() method arguments in the same manner as described in Section 2.2. To specify the model by file, one instead uses the “Model file” field to select a model file, as described in Section 2.3.

For either kind of model, it is also possible to use the “Waypoints file” field to specify a file of saved waypoints to be loaded along with the model. As with all externally loaded waypoint data, the waypoints must match the current model structure. Waypoints are described in Section 7.3.1.

-

•

To save the startup model, click the Save button at the bottom of the dialog.

-

•

To clear the startup model (so that no model is loaded), click the Clear button followed by the Save button.

-

•

To load a specified model immediately, click the Load Model button.

2.5.1 Specifying models from the command line

As an alternative to setting the startup model, one may instead use the -model <classOrFileName> command line option to specify a model to load when ArtiSynth starts up. This can be useful when running ArtiSynth from a script. The <classOrFileName> argument may be either a class name or a .art file name. If a class name is specified and build() method arguments are also required, these may be listed within square brackets ([ ]) separated by white space. For example, to load the model class projects.MyModel and pass it the build() arguments “-size 50”, one can invoke ArtiSynth from the command line using

> artisynth -model projects.MyModel [ -size 50 ]

Models specified from the command line override the specified startup model. To ensure that no model is loaded, one may specify

> artisynth -model none

2.6 Simulating a model

Once a model is loaded, simulation of the model can be started, paused, single-stepped, or reset using the play controls (Figure 4) located at the upper right of the ArtiSynth window frame. Play controls are discussed in more detail in Section 7.2.1.

2.7 Other toolbar controls

The ArtiSynth application contains a toolbar that runs along the top of the frame. The right side contains the play controls shown in Figure 4.

When a grid is enabled in the viewer (Section 3.7), a text box appears in the center of the toolbar displaying the current grid units (Section 3.7.1).

The left side of the toolbar contains the following buttons:

| NavPanel: | Shows or hides the navigation panel (Section 4.2) | |

| Reset state: | Resets the simulation state at time 0 to the current state. | |

| Rerender: | Rerenders all viewers and displays. | |

| Enable real-time: | If pressed (the default setting), forces simulations to run no faster than real time. |

If real-time is enabled (via the last button), the ArtiSynth scheduler will try to make the apparent simulation speed equal to real time. Simulations can of course run much slower than real time if they involve complex models with many degrees of freedom (such as large finite element models). However, for simpler models, real-time can also increase the overall simulation time, which is why the option to disable real-time is provided.

2.8 Saving a model

An ArtiSynth model can be saved to a file to be reloaded and used later. Selecting “Save model as ...” from the File menu will bring up a dialog that lets you select the name and directory for the model file (Figure 5). If a model file has already been specified, then one can save to it again by selecting the Save model menu item. ArtiSynth model files are text-based and are typically identified by the extension .art.

When using the “Save model as ...” menu item, the user may choose the following options:

- Save waypoint data:

-

Causes the state data for any valid waypoints (Section 7.3) to be saved (within the file) in addition to the waypoint locations. This is optional because a large number of waypoints may significantly increase the file size for models with a large state sizes.

- Core components only:

-

Saves only those components which are present in the main artisynth_core package. Any non-core components, and any other components which have a hard dependency on them, will not be written, and the user will be advised of this via a message dialog. The root model (Section 4.1) is saved as a pure instance of RootModel, instead of the application-specific class that was used to build it. This means that any properties or class overrides specific to the application root model class will not be present in the saved model. The advantage to storing a model using only core components is that it can be loaded by any other user running the same ArtiSynth version, without needing access to any application-specific classes.

2.9 Setting the external classpath

As mentioned above, the classpath(s) for models declared outside of artisynth_core must be made visible to ArtiSynth so that they can be found and loaded. Detailed information on this topic is given in the section “Making external models visible to ArtiSynth” of the ArtiSynth Installation Guide.

An easy way to make classpaths visible to ArtiSynth is to add them to the external classpath, which is a list of top-level class folders and/or .JAR files containing the classes required to run external models. These may include both model classes and any external Java libraries that they require.

The external classpath is contained in a file named EXTCLASSPATH in the user configuration folder (Section 1.1). This file can be edited directly from ArtiSynth by selecting “External classpath ...” from the Settings menu, which will open the editing dialog shown in Figure 6.

The current class folders and JAR files are listed, one per line, in the large panel at the left. If the external classpath is empty, this panel will be blank. New class folders or JAR files can be added using the “Add class folder” and “Add JAR file” buttons at the right, which invoke file choosers appropriate to the file type. Existing entries can be selected and then edited, moved up or down in the list (using the up/down arrow buttons), or deleted (using the X button). When editing is complete, the updated external classpath can be saved using the Save button at the bottom.

ArtiSynth must be restarted for external classpath changes to come into effect.

2.10 The ArtiSynth working folder

ArtiSynth maintains the notion of a working folder, which is the default folder (or directory, in Unix parlance) under which the files used to store various types of model information are stored. This includes model files, as described above, along with other files such as those used to store waypoints, probe configurations, or probe data (Section 8).

Chooser dialogs for these files will generally be initialized to the working folder if their files have not been previously set.

The working folder is initialized to the system working folder from which the ArtiSynth application is started. Once ArtiSynth is running, it can be set by choosing “Set working folder ...” from the File menu, or by calling

ArtisynthPath.setWorkingFolder (file)

in code. When a model is saved (Section 2.8), the working folder is saved with it and restored when the model file is subsequently loaded.

3 The Viewer

The viewer provides interactive graphical rendering of the ArtiSynth model and permits selection of its components. A viewer is integrated into the ArtiSynth main frame; additional viewers can be created if necessary.

3.1 Viewer Toolbar

Each viewer is provided with a toolbar (Figure 7) equipped with icons for controlling the viewpoint (Section 3.2) and clipping planes (Section 3.8). The toolbar for the main viewer appears vertically at the lower left of the main frame, while toolbars for additional viewers appear horizontally at the top. Each is an instance of Java’s JToolBar, and so can be moved and docked accordingly.

3.2 Viewpoint control

The viewpoint can be controlled interactively using mouse drag actions. There are three such actions:

- Rotate

-

Rotates the viewpoint about the viewer center point. By default, this rotation is constrained so the viewer “up” direction remains vertical in the view plane, but this can be changed using the viewer’s rotationMode property (Section 3.10).

- Translate

-

Translates the viewpoint in a plane perpendicular to the line of sight.

- Zoom

-

Zooms in or out by moving the viewpoint along the line of sight.

The mouse button and modifier key combinations required to effect these actions depend on the application’s mouse bindings, which by default are set to either ThreeButton, TwoButton, or OneButton depending on the number of available mouse buttons. Button/key combinations for each of these is described in the following table,

| Action | ThreeButton | TwoButton | OneButton |

|---|---|---|---|

| Rotate | MMB | LMB+ALT | LMB+ALT |

| Translate | MMB+SHIFT | LMB+ALT+SHIFT | LMB+ALT+SHIFT |

| Zoom | MMB+CTRL | LMB+ALT+CTRL | LMB+ALT+CTRL |

where MMB and LMB denote the middle and left mouse buttons. If a mouse wheel is present, then this can also be used to execute zoom actions.

Mouse bindings can also be set explicitly by the user and alternative bindings are available; see Section 3.11.

3.3 Setting aligned axis viewpoints

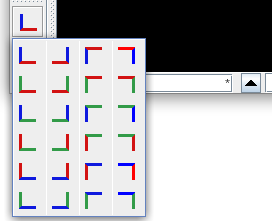

Predetermined viewpoints can also be selected using the align axis button located on the viewer control bar. Clicking on this button produces a popup menu with icons for different axis-aligned views (Figure 8). Each view is indicated by the two axes perpendicular to the line of sight, with the X, Y, and Z axes illustrated by red, green, and blue lines respectively. Some examples are:

| Z axis up, X axis to the right. | |

| Z axis up, X axis to the left. | |

| Y axis up, X axis to the right. | |

| Y axis down, X axis to the right. | |

| Z axis up, y axis to the right. | |

| Z axis up, y axis to the left. |

The align axis button itself displays the most recently selected axis-aligned view, and the popup menu shows this view in the upper left corner. Reselecting the current view will simply realign the viewer’s viewpoint to the current view; hitting the ‘v’ key from within the viewer (Section 3.12) will do the same.

3.4 Adding additional viewers

Additional viewers can be created by selecting View > New viewer from the main menu. Each viewer provides independent viewing and selection control for the current model.

3.5 World coordinate axes

Hitting the ’a’ key from within the viewer enables or

disables drawing of the world coordinate axes. By default, these are

drawn as simple lines, with the ![]() ,

, ![]() and

and ![]() axes colored red,

green and blue, respectively, and the axis length computed

automatically based on the model size.

axes colored red,

green and blue, respectively, and the axis length computed

automatically based on the model size.

|

|

3.6 Orthographic vs. perspective projection

The user can toggle between orthographic and perspective projection by selecting View > Orthographic view or View > Perspective view from the main menu. Toggling can also be achieved using the ‘o’ key shortcut (Section 3.12) within the viewer.

3.7 Viewer grid

Hitting the ‘g’ key within the viewer enables or disables a grid (Figure 10). Grid cells are square and appear in two resolutions, with major cells subdivided into a number of minor cells. Major cells are typically rendered more brightly than minor cells. By default, the grid computes the cell sizes automatically based on the current viewer zoom-level. However, it is possible to set an explicit grid resolution (see 3.7.1).

The grid is located in the plane perpendicular to the line of sight of the most recently selected axis-aligned view. To change the grid plane, select a new axis aligned viewpoint (Section 3.3).

3.7.1 Grid units

When the grid is enabled, a box labeled Grid: appears in the toolbar on top of the main ArtiSynth frame which gives the current resolution of the grid, displayed as S/N, where S is the size of each major grid cell and N is the number of subdivisions per cell. If there are no subdivisions, then the /N is omitted. For example, in Figure 10, this appears as Grid: 1/10, which means that the major grid cells have a size of 1.0 and are each divided into 10 subdivisions. The numeric value of the ratio S/N gives the minor cell size.

By default, the grid automatically resizes itself to the current viewer zoom level, choosing well-rounded numbers for the grid cell size. Auto-sizing can be enabled or disabled by right-clicking on the Grid: label and choosing Turn auto-sizing on or Turn auto-sizing off, as appropriate. The user can also specify an explicit value for the grid resolution by entering the desired S/N value (or just an S value) into the Grid: box. Specifying an explicit value will disable auto-sizing, unless S is specified as 0 or the special value * is entered, both of which will re-enable auto-sizing.

3.7.2 Axis labeling

Hitting the ‘l’ key within the viewer enables or disables labeling of the major divisions along the horizontal and vertical axis (Figure 11). The division lines along which these labels appear are automatically adjusted so as to ensure proper label visibility, and do not necessarily correspond to the x, y, or z axes.

It is possible to control various properties associated with axis labeling, such as which axes are labeled, and the label size and color. See the next section on Grid properties.

3.7.3 Grid properties

The grid has a number of properties that can be set by right-clicking in the viewer and choosing Set viewer grid properties (or by right-clicking on the Grid: label and choosing Set properties). This will bring up a property dialog, such as that shown in Figure 12.

Properties that can be set include:

- resolution

-

Grid resolution, as described above.

- autoSized

-

If true, causes the grid resolution to be recomputed as the user adjusts the view position, orientation, and zoom.

- minCellPixels

-

Minimum number of pixels that should appear in a minor cell division when autosizing.

- majorColor

-

Color to use for the major axis lines.

- minorColor

-

Color to use for the minor axis lines.

- xAxisColor

-

Color to use for the grid line that corresponds to the world y axis, or the horizontal axis if lockAxesToWorld is false.

- yAxisColor

-

Color to use for the grid line that corresponds to the world y axis, or the vertical axis if lockAxesToWorld is false.

- zAxisColor

-

Color to use for the grid line that corresponds to the world z axis.

- lineWidth

-

Width of the grid lines, in pixels.

- position

-

Translation position of the grid, in world coordinates.

- orientation

-

Orientation of the grid, in world coordinates.

- lockAxesToWorld

-

If true, forces the grid to stay aligned with the orientation and position of the world axes. In particular, the horizontal and vertical axes will always be parallel to one of the x, y, or z world axes, the grid center will be a multiple of major cell sizes from the origin, and axis labels will be set relative to the world origin.

- useWorldOrigin

-

If true, causes the principal horizontal and vertical axes to be aligned with the world origin. Otherwise, the axes will be aligned with the grid center. This property can only be true if lockAxesToWorld is also true.

- xAxisLabeling

-

Enables labeling of the x axis.

- yAxisLabeling

-

Enables labeling of the y axis.

- labelSize

-

’em’ size of the label text, in pixels.

- labelColor

-

If set, specifies the color used to draw the label text. Otherwise, the major axis color is used.

3.8 Clipping planes

The user can add clipping planes to the viewer. These are useful for restricting what is rendered and allowing a better view of interior structures, as shown in (Figure 13).

3.8.1 Adding and removing

To add a clipping plane, left click on the add clip plane

button ![]() located on the

viewer toolbar. This will create a clipping plane located in the plane

perpendicular to the current line of sight.

located on the

viewer toolbar. This will create a clipping plane located in the plane

perpendicular to the current line of sight.

It will also add to the viewer toolbar a clip plane icon

![]() for controlling the

clipping plane. Right-clicking on this icon will bring up an option

menu.

for controlling the

clipping plane. Right-clicking on this icon will bring up an option

menu.

To delete a clipping plane, right-click on its icon and select Delete.

3.8.2 Moving

A clip plane is associated with a coordinate system and can be moved and/or rotated by dragging on the trans-rotate transformer located at its coordinate system origin. The clip region is the half space lying in the direction of the +z axis.

The transformer itself can be made invisible/visible by right-clicking on the clip plane icon and selecting Hide transformer or Show transformer.

3.8.3 Offsets

The clipping region is the half space lying in the direction of the +z axis of the plane’s local coordinate system. By default, clipping is actually offset by a small distance along the +z axis, so that small objects (such as points) lying in the x-y plane remain visible. The amount of this offset is controlled by the plane’s offset property, which is set to a nominal default value. To control this property directly, right-click on the clip plane icon and select Set properties. This will bring up a panel which allows the offset to be adjusted.

3.8.4 Enabling/disabling

Left clicking on the clip plane icon will enable/disable

clipping. Disabling clipping allows the plane to be used as a regular

movable grid. When clipping is disabled, the icon

will change to the form

![]() .

.

3.8.5 Slicing mode

Clipping planes can be placed in a slicing mode, whereby half-spaces in both the positive and negative z directions are clipped. The result is a small slice about the local x-y plane (Figure 13, right). The width of this slice is controlled by the plane’s offset property, as described above.

To enable or disable slicing, right-click on the clip plane icon and select Enable slicing or Disable slicing.

3.8.6 Other features

- Properties

-

Various properties associated with the plane, such as its color, line width, cell resolution, etc., can be set explicitly by the user. To do this, right-click on the icon, select Set properties, and edit the resulting property panel. Most properties are the same as those described for the main viewer grid in 3.7.3.

- Grid visibility

-

To make the grid invisible/visible, right-click on the icon and select Hide grid or Show grid.

- Alignment with world axes

-

The clip plane can be aligned so that it’s normal lies along the positive or negative direction of either the x, y, or z world axes. Right-click on the icon and select the appropriate option. Clipping is performed so that the half-space lying in the direction of the normal is clipped.

- Alignment with current line of sight

-

To align the clipping plane so that it is perpendicular to the current line of sight, right-click on the icon and select Reset.

3.9 Indicating 3D positions with the mouse

It is possible to use a viewer in combination with a mouse to specify the position of a 3D point in space. This is commonly employed in the editing operations described in Section 16.

To specify a point, the user left-clicks the mouse in the viewer, at the screen position located over the point’s desired position. The 3D position is then determined by intersecting the ray indicated by the mouse clock with some appropriate surface or plane. Typically, a plane perpendicular to the viewing direction and passing through the model’s center is used. Alternatively, some interactions provide a constrain to plane option, which causes the ray to be intersected with a viewer clipping plane (Section 3.8), providing more precise control over the point’s position. This requires that the viewer presently contain at least one clipping plane. If more than one clipping plane is present, the first one is used.

In other applications, the desired point may be known to lie on a 3D surface, in which case the position is determined by intersecting the ray with a 3D surface mesh.

3.10 Viewer properties

Viewers export a number of properties that control various aspects of their look and feel. Some of these can be modified collectively for all viewers by choosing “Settings > Viewers ...” from the main menu, which opens a viewer settings dialog (Figure 14).

Various properties can be set by this dialog, as described below. Clicking the Save button will save the current settings to the user’s preferences (Section 11.2) so that they will be set automatically when ArtiSynth is restarted.

Properties set by the viewer settings dialog include:

- backgroundColor

-

Color of the viewer background.

- selectionColor

-

Color used to highlight selected items.

- axisDrawStyle

-

Controls how world coordinate axes are drawn (Section 3.5), with LINE and ARROW specifying simple lines and solid arrows, respectively.

- axisRadiusRatio

-

A ratio which can be used to determine the radius for an axis when the radius is not explicitly specified. The radius is computed by multiplying the ratio by the axis length. This is typically used when rendering coordinate axes as solid arrows and has a default value of 0.016.

- rotationMode

-

Controls how the eye-to-world rotation is adjusted when the mouse is used to perform a rotate action (Section 3.2). The default value is FIXED_VERTICAL, which constrains the viewer’s “up” vector to remain vertical with respect to the view plane, at the expense of preventing the eye-to-world rotation from being adjustable to an arbitrary value. Alternate values include CONTINUOUS, which enables a track-ball type rotation that does allow arbitrary adjustment of the eye-to-world rotation, and OFF, which disables rotation adjustment.

- defaultAxialView

-

Sets the default axis alignment indicating how the 3D world axes correspond to the horizontal “right” and vertical “up” view plane directions. Each setting takes the form

_

_ , where

, where  is the

world axis pointing right and

is the

world axis pointing right and  is the axis pointing up, and

is the axis pointing up, and  and

and

can each be either X, Y, Z, NX, NY,

or NZ, indicating the positive or negative

can each be either X, Y, Z, NX, NY,

or NZ, indicating the positive or negative  ,

,  or

or  axis.

axis. - ellipticCursorSize

-

Size of the elliptic cursor (Section 4.3.2) in the horizontal and vertical directions. The default value is

.

. - surfaceResolution

-

Controls the number of faces or segments used for rendering built-in curved primitives, such as cylinders and spheres. For cylinders, it controls the number of sides, while for spheres it controls the number of longitudinal slices. A larger number produces a smoother effect at increased graphical cost. The default value is 32.

For OpenGL based viewers, the following properties are also provided to control how transparency is rendered:

- transparencyFaceCulling

-

Enables or disables face culling when rendering transparency.

- transparencyBlending

-

Enables or disables transparency blending (via glEnable() or glDisable() using GL_BLEND) when rendering transparency.

- blendSourceFactor

-

Specifies the first (source) argument to glBlendFunc().

- blendDestFactor

-

Specifies the second (destination) argument to glBlendFunc().

3.10.1 Viewer-specific properties

Viewer properties can also be set on a per-viewer basis. To do this, invoke the context menu (usually right-click) in the viewer when nothing is selected, and choose Set viewer properties. Individual properties include all those described above (except with defaultAxialView renamed to axialView), together with the following additional properties:

- axisLength

-

Axis lengths used to render the world axes (Section 3.5).

- viewControlMask

-

If set to ALONG_X_ONLY or ALONG_Y_ONLY, mouse-based view control inputs are restricted to those in the x or y screen directions, respectively. This makes it easier to limit changes in the view point. The default value is NONE (no restriction).

- eye

-

Location of the eye position, in world coordinates.

- center

-

Location of the viewing frustum center, in world coordinates.

Setting a viewer-specific property, such as the background color, will generally cause it to have a value that differs from its counterpart in the viewer settings (because the value was set for only a single viewer). On the other hand, properties set in the viewer settings will be applied to all open viewers.

3.11 Mouse Bindings

The ArtiSynth GUI was originally designed for a three-button mouse, in which the left button is used for selection, the middle button controls the viewpoint, and the right button is used to activate the context menu. These are used in conjunction with the modifier keys SHIFT and CTRL to effect different actions.

For systems that do not have a three-button mouse, ArtiSynth by default detects the number of mouse buttons and adjusts the mouse bindings so that the ALT key emulates the middle button and the META key emulates the right button.

The META key is usually associated with either the COMMAND key (Mac) or the WINDOWS key.

Mouse bindings can also be explicitly set by the user, by choosing “Settings > Mouse ...” from the main menu, which opens a mouse bindings dialog (Figure 15). This allows the user to change the bindings, and also for any given binding describes the button/key combinations to effect various actions. If the “Auto detect” checkbox is selected, then the bindings are determined automatically from the number of available mouse buttons. Unchecking this box allows the bindings to be set explicitly using the Bindings selector. The dialog also allows control of the scale factor used for mouse wheel zoom actions.

Clicking the Save button in the mouse bindings dialog will save the current bindings to the user’s preferences (Section 11.2) so that they will be set automatically when ArtiSynth is restarted. Mouse bindings can also be specified explicitly at startup using the -mousePrefs <bindings> command line option.

Currently, there are five bindings available:

- ThreeButton

-

Default bindings for a three-button mouse.

- TwoButton

-

Default bindings for a two-button mouse. The middle mouse button is emulated with the ALT key.

- OneButton

-

Default bindings for a one-button mouse. The middle and right mouse buttons is emulated with the ALT and META keys.

- Laptop

-

Legacy bindings for a two-button mouse.

- Mac

-

Legacy bindings for a Mac type one-button mouse.

Tables showing the button and modifier key combinations that effect different actions for each of these are given below, with LMB, MMB, and RMB denoting the left, right and middle mouse buttons. Actions marked with an asterisk (*) are drag actions which can have their modifier keys invoked or removed during a drag operation. Button/key combinations for ThreeButton, TwoButton, and OneButton are:

| Action | ThreeButton | TwoButton | OneButton |

|---|---|---|---|

| Viewpoint control (Section 3.2) | |||

| Rotate view | MMB | LMB+ALT | LMB+ALT |

| Translate view | MMB+SHIFT | LMB+ALT+SHIFT | LMB+ALT+SHIFT |

| Zoom view | MMB+CTRL | LMB+ALT+CTRL | LMB+ALT+CTRL |

| Component selection (Section 4.3) | |||

| Select components | LMB | LMB | LMB |

| Multiple selection | LMB+CTRL | LMB+CTRL | LMB+CTRL |

| Elliptic selection | LMB | LMB | LMB |

| Elliptic deselection |

LMB+SHIFT | LMB+SHIFT | LMB+SHIFT |

| Resize elliptic cursor | LMB+SHIFT+CTRL | LMB+SHIFT+CTRL | LMB+SHIFT+CTRL |

| Context menu | RMB | RMB | LMB+META |

| Manipulator controls (Section 5.2) | |||

| Move dragger | LMB | LMB | LMB |

| Dragger constrain |

LMB+SHIFT | LMB+SHIFT | LMB+SHIFT |

| Dragger reposition |

LMB+CTRL | LMB+CTRL | LMB+CTRL |

while those for Laptop and Mac are:

| Action | Laptop | Mac |

| Viewpoint control (Section 3.2) | ||

| Rotate view | LMB | LMB+ALT |

| Translate view | LMB+SHIFT | LMB+ALT+SHIFT |

| Zoom view | LMB+ALT | LMB+ALT+META |

| Component selection (Section 4.3) | ||

| Select components | LMB+CTRL | LMB |

| Multiple selection | LMB+SHIFT+CTRL | LMB+META |

| Elliptic selection | LMB+CTRL | LMB |

| Elliptic deselection |

LMB+SHIFT+CTRL | LMB+SHIFT |

| Resize elliptic cursor | LMB+SHIFT+CTRL | LMB+SHIFT+CTRL |

| Context menu | RMB | LMB+CTRL |

| Transformer control (Section 5.2) | ||

| Move dragger | LMB | LMB |

| Dragger constrain |

LMB+SHIFT | LMB+SHIFT |

| Dragger reposition |

LMB+ALT | LMB+ALT |

3.12 Keyboard shortcuts

When the viewer has the keyboard focus, the following key shortcuts are available:

| Key | Operation |

|---|---|

| q | quit ArtiSynth |

| t | toggle time line visibility |

| z | undo last command |

| Play controls (Section 2.6): | |

| p or SPC | play/pause |

| s | single step |

| r | reset |

| Viewer controls: | |

| v | reset view (Section 3.2) |

| o | toggle orthographic/perspective view (Section 3.6) |

| a | toggle visibility of axes showing world coordinates |

| g | toggle viewer grid (Section 3.7) |

| l | toggle viewer grid labels |

| Selection and transformer (Sections 4.3 and 5.2): | |

| ESC | select parent of last selection |

| c | clear selection |

| d | reset elliptic cursor size to default |

| w | set current transformer frame to world coordinates |

| b | set current transformer frame to body/local coordinates |

4 Component Navigation and Selection

An ArtiSynth model is composed of a hierarchical arrangement of model components (each of which implements the interface ModelComponent), some of which may themselves be models. The graphical interface allows users to navigate this hierarchy and select individual components. Selected components can then be edited, or have specific properties modified or attached to probes or control panels.

4.1 The component hierarchy

An example component hierarchy is shown in Figure 16. At the top is a root model (class RootModel), in this case named Rigid Body Spring. The root model in turn contains a list of models, one of which is a mechanical model named msmod, which here contains particles and rigid bodies.

It is important to node that in the component hierarchy, any collection of components is itself a component (usually an instance of ComponentList). This provides automatic “grouping” of components of like type, but does introduce additional levels into the hierarchy. Hence the particle red is a child not of msmod, but rather the component list particles.

4.1.1 Component names and numbers

Model components may be assigned a string name; at the time of this writing names may not begin with a digit, have zero length, contain the characters ‘.’ or ‘/’, or equal the reserved word this. Components which do not have an assigned name are called nameless.

All components have a number, even if they do not have a name. The number is assigned automatically when the component is added to the parent, and is guaranteed to be persistent until the component is removed from the parent.

4.1.2 Component path names

The names and/or numbers of a component’s ancestors can be used to form a component path name. This path has a construction completely analogous to Unix file path names, with the ‘/’ character acting as a separator. Absolute paths start with ‘/’ and begin with the root model. Relative paths omit the leading ‘/’ and can begin lower down in the hierarchy. The absolute path name of the red particle in Figure 16 would be

/Rigid Body Spring/models/msmod/particles/red

For nameless components in the path, their numbers can be used instead:

/Rigid Body Spring/models/msmod/rigidBodies/1

Numbers can be used even for components that have names. Hence a path name consisting only of numbers, as in

/0/0/0/3/1

is legal, although it most likely to appear only in machine-generated output.

4.2 Navigation panel selection

A navigation panel in the main ArtiSynth frame allows direct

navigation of the component hierarchy. The panel can be

open or closed by clicking on the main toolbar icon

![]() .

.

Left clicking on any component in the navigation panel selects that component. Clicking while pressing the CTRL key (or the CMD key on some platforms, such as Mac) allows selection of multiple components. Clicking while pressing the SHIFT key allows selection of a range of components.

4.2.1 Large numbers of nameless components

In some cases, such as finite element models, the number of child components can be very large (on the order of thousands). In order to keep the navigation panel size manageable, the number of nameless children displayed is limited to a set number (currently 100). If the number of nameless children exceeds this number, the display will be augmented with an expand icon >>>. Clicking on this will expand the display to include all nameless components, and the expand icon will be replaced by a contract icon <<<. Clicking on the contract icon will cause the extra nameless components to be hidden again. This is illustrated in Figure 18.

|

|

4.3 Viewer selection

Components that are rendered in the viewer can generally be selected by variety of methods (the exception is for a few renderable components that do not support selection). These methods include click, box, and elliptic selection. The top two icons in the selection toolbar at the left of the ArtiSynth frame control the current selection method. In addition, hitting the ‘c’ key from within the viewer (Section 3.12) clears the current selection.

4.3.1 Click and box selection

Click and box selection are enabled by the arrow icon at the top of the selection toolbar:

Click selection involves left clicking on a component, causing it to be selected. Selection of multiple components is enabled by left clicking with a modifier key, which is usually CTRL but may be different for some legacy mouse bindings (Section 3.11).

Click selection selects only those components which are actually visible to the viewer; components which are hidden cannot be selected this way.

Box selection is effected by left-clicking and dragging in the viewer, causing the selection of all components rendered within the resulting drag box. Because this often results in the selection of more components than desired, it may be useful to employ a selection filter (Section 4.3.3). Any components within the drag box which are already selected will be deselected.

Box selection acts on all (filtered) components within the view frustum defined by the drag box, including those which are hidden from view.

4.3.2 Elliptic selection

Elliptic selection is enabled by the elliptic icon near the top of the selection toolbar:

This causes an additional elliptic cursor (which defaults to a circle) to be drawn around the mouse cursor. Selection is effected by dragging, and causes all visible objects within the ellipse to be selected. The selection process is cumulative, with subsequent drags selecting additional components. As with all selection operations, a filter can be set to restrict the components that are selected (Section 4.3.3). Generally, the drag select operation requires no modifier keys, although it may with some legacy mouse bindings (Section 3.11).

It is also possible to deselect components in the same way, by using the SHIFT modifier key to cause drag operations to cumulatively deselect components.

Elliptic selection selects only those components which are actually visible to the viewer; components which are hidden cannot be selected this way.

The elliptic cursor used for selection can be resized, either interactively, or by setting the ellipticCursorSize property of the viewer (Section 3.10). To interactively change the cursor size, initiate a drag operation with the CTRL and SHIFT modifiers. Finally, the ‘d’ key shortcut within the viewer will cause the cursor to be reset to its default size.

4.3.3 Selection filtering

It is possible to limit viewer selection to components of a specific type. This can be done using the selection filter widget at the bottom left of the main ArtiSynth frame Figure 19.

To enable filtering, type into the widget text box the class name of the component type you wish to restrict filtering to. It is generally only necessary to enter the leaf name of the class (e.g., Particle or AxialSpring), and the system will then find the full class name by searching the ArtiSynth class path.

Once filtering is enabled, only components which are instances (including subclasses) of the specified type will be selectable.

Previously selected filters can be recalled using a history list accessible using the leftmost arrow button on the selection widget.

To remove selection filtering, enter the special filter *, either by typing this in the text box, or using the history list.

4.4 Selection display

The selection display Figure 20 at the bottom of the main ArtiSynth frame shows the full path name of the last component added to the selection list. This is useful for identifying components in detail.

If no components are selected, then the selection display is blank.

The selection display is useful for disambiguating situations where it is not clear what component we have actually selected in the viewer. For example, FEM models keep their surface mesh contained within a descendant component. Selecting the surface mesh will cause this container component to be selected and highlighted, making it appear as though the FEM model itself is selected rather than the container. Checking the selection display makes it clear what component has actually been selected. If desired, one can easily navigate to one of the ancestor components using parent selection, as described in the next section.

4.5 Selecting parent and ancestor components

Sometimes, when you select a component, you actually want to select one of it’s ancestor components.

There are several ways to do this:

-

1.

Hit the escape (ESC) key within the viewer window. This will select the parent of the currently selected component. Hitting escape repeatedly is a fast way to proceed up the component hierarchy.

-

2.

Click on the “up” arrow located at the left of the selection display (Figure 20). This will also select the parent of the currently selected component.

Parent selection is particularly useful in the commonly occurring situation where a composite component is not rendered and therefore not selectable in the viewer. For instance, suppose we wish to select a FEM model. One can select any renderable descendant of the model, such as a node, element, or its surface mesh (if displayed), and then use repeated parent selection until the model itself is selected.

4.6 Highlighting selected components

Selected components are rendered in the viewer using a special selection color (yellow at the time of this writing). It is important to note that descendants of a selected component are not presently rendered in any special way. For instance, if an FEM is selected, it’s nodes and elements will be rendered normally.

While this has the potential to be confusing, we have not yet found this to be problematic, as the navigation panel and selection display provide alternative indicators as to what is currently selected.

4.7 Selecting FEM nodes

A specialized tool is available for selecting FEM nodes, because it is often necessary to identify collections of nodes for connecting to rigid bodies or other FEM models, or to set localized properties and/or boundary conditions.

|

|

To open the node selection tool, first select the FEM model containing the nodes, and then invoke the context menu (usually via right-click) and choose “Select nodes ...”. A node selection tool will appear, as shown in Figure 21. From top to bottom, this contains several controls:

-

1.

A selection mode chooser that specifies how nodes are selected, possibly followed by mode-specific fields to adjust the selection behavior;

-

2.

An instruction box describing what action the user should take;

-

3.

A surfaceNodesOnly check box that allows selected nodes to be restricted to the FEM model’s surface;

-

4.

Buttons for clearing, growing or shrinking the selection, reducing the selection to its boundary, or for filling it in;

-

5.

Buttons for saving/loading a list of the selected nodes to/from a file, or for attaching or detaching selected nodes from other bodies.

While a node selection tool is open, GUI selections are restricted to certain components, usually nodes of the indicated FEM model. If surfaceNodesOnly is checked, selection is restricted to the FEM surface nodes. Selection is also held in a “multiple component” mode, equivalent to holding down the multiple selection key (usually CTRL), so that the selection can be easily edited and is not reset with each selection action.

|

|

The different selection modes and their parameters include:

- INDIVIDUAL

-

- PATCH

-

Nodes are selected, on the mesh surface, within a patch region defined by a set of faces for which the bend angle between adjacent faces is less than or equal to a specified maximum bend angle. The bend angle is defined as the absolute value of the angle between two faces along their common edge, such that parallel faces have a bend angle of

and perpendicular ones have a bend

angle of

and perpendicular ones have a bend

angle of  . Within the tool, the maximum bend angle is

specified (in degrees) by the field maxBendAngle. To find the

patch nodes, the user selects a node within the desired patch

area. Starting with the node’s adjacent faces, the patch is then grown

outwards to find all neighboring faces such that the bend angle

between them does not exceed maxBendAngle (Figure

22, left).

. Within the tool, the maximum bend angle is

specified (in degrees) by the field maxBendAngle. To find the

patch nodes, the user selects a node within the desired patch

area. Starting with the node’s adjacent faces, the patch is then grown

outwards to find all neighboring faces such that the bend angle

between them does not exceed maxBendAngle (Figure

22, left). - EDGE_LINE

-

Nodes are selected, on the mesh surface, along an edge line defined by faces meeting at a bend angle greater than or equal to a specified minimum bend angle. Within the tool, this minimum angle is specified (in degrees) by the field minBendAngle. To find edge line nodes, the user selects a node lying along the desired edge line. The line is then followed from node to node, by locating edges with a large enough bend angle.

EDGE_LINE selection is illustrated in Figure 23, and the following fields adjust its behavior:

- minBendAngle

-

Minimum bend angle, described above.

- maxEdgeAngle

-

Specifies (in degrees) the maximum edge angle between two adjacent edges along the edge line. Line following is terminated when the angle between the current edge and the next edge exceeds this threshold.

- allowBranching

-

If selected, allows the edge line to branch in different directions. Otherwise, edges are followed sequentially so as to minimize the edge angle between them.

- DISTANCE

-

Nodes are selected based on being within a prescribed distance of a polygonal mesh, which may be the surface mesh for a rigid body or FEM model, or some other mesh component. The distance threshold is specified by the field distance. To select nodes, the user may select any mesh component containing a polygonal mesh. The user may also select a rigid body or FEM model, which will cause the body’s surface mesh to be used for the distance calculation.

The following fields adjust the behavior of DISTANCE selection:

- distance

-

Distance threshold, described above.

- useSignedDistance

-

If selected, causes the distance computation for closed meshes to be signed, so that nodes inside the mesh will have a negative distance. This means that for a non-negative distance threshold, nodes inside the mesh will always be selected.

- surfaceNodesOnly

-

If checked, the selection is restricted to the FEM model’s surface.

- MINIMUM_PATH

-

In this mode, the user selects an individual node, and the tool then selects a minimum path of nodes between it and the previously selected node. This is particularly useful for “drawing” the boundary of a nodal region on the FEM model’s surface.

If surfaceNodesOnly is checked, the path will be restricted to the FEM surface; otherwise, the path may proceed through the FEM interior.

When forming the path, the tool chooses from adjacent nodes based on the topology induced by the FEM elements. This can sometimes lead to a path that is less minimal than if nodes could be chosen arbitrarily, particularly for quadratic hex, wedge and pyramid elements.

|

|

The user is free to change modes during the selection process. Because selection is held in multiple selection mode, it is easy to edit the selection. In particular, INDIVIDUAL selection can be used for fine editing of selections obtained using PATCH, EDGE_LINE, DISTANCE, or MINIMAL_PATH.

Below the surfaceNodesOnly check box, the tool contains a number of buttons:

- Clear

-

Unselects all the nodes.

- Grow

-

Enlarges the current selection to include adjacent nodes.

- Shrink

-

Reduces the current selection by removing nodes on the boundary.

- Boundary

-

Reduces the current selection to include only its boundary nodes (Figure 22, right).

- Fill

-

Fills a region in the current selection. After clicking this button, the user selects a node inside the desired region. The selection is then grown outward from the selected node until it reaches the region’s boundary.

- Attach nodes

-

Attaches the selected nodes to another body which is either a rigid body or an FEM model. The body may be chosen by selecting it directly, or by selecting one of its component meshes. Nodes which are currently attached are not attached to the body.

- Detach nodes

-

Detaches all selected nodes from any body or particle that they are currently attached to.

- Save

-

Saves the nodes to a file that has been previously specified using either “Save as ...” or “Load ...”.

- Save as ...

-

Saves the nodes to a user-specified text file. The format consists simply of integer node numbers (with respect to the selection tool’s FEM model), separated by white space. More details on the file format are given in the section “Selecting nodes in the viewer” of the ArtiSynth Modeling Guide.

- Load ...

-

Loads the selected nodes from a text file, the format for which is described under “Save as ...”.

5 Model Manipulation

Various tools located within the selection toolbar at the left of the main ArtiSynth frame allow models to be manipulated in various ways. These include modifying component locations, orientations, and geometry using the transformer tools (Section 5.2), exerting point forces on selected components using the pull controller (Section 5.3), and adding marker points to certain components types (Section 5.4).

The behavior of these tools is somewhat context dependent. For example, the transformer tools will only transform those transformable components which implement the TransformableGeometry interface. The behavior may also vary depending on whether or not simulation is in progress.

5.1 Dragger fixtures

The transformation tools employ the dragger fixtures shown in Figure 24, which allow 3D geometrical transformations to be performed within the viewer.

- Translator

-

Effects a translation. The x, y, and z axes are indicated by red, green, and blue lines. Dragging any line causes a one-dimensional motion along the associated axis. Dragging one of the boxes causes a two-dimensional motion in the associated plane.

- Rotator

-

Effects a rotation. Rotation about the x, y, and z axes is indicated by red, green, and blue circles. Selecting and dragging along one of these circles produces a rotation about the corresponding axis.

- TransRotator

-

Combines the translator and rotator into a single tool. One difference is that the axes of the transRotator move with any rotation, and so operations are done with respect to the transRotator coordinate frame at the beginning of the drag.

Under the default mouse bindings, the basic drag operations involving these fixtures are invoked using the left mouse button with no modifier keys. Additional modifier keys allow constrained transformation or repositioning of the fixture, as described below.

5.2 Transformer tools

A number of transformer tools use the dragger fixtures described above to translate, rotate, and scale components. Once a tool is activated, then selecting one or more transformable components will cause the corresponding dragger fixture to appear in the viewer at the components’ location. If a single component is selected and that component is associated with a coordinate frame (by implementing the HasCoordinateFrame interface), then the dragger’s initial position and orientation are aligned with this coordinate frame. Otherwise, the dragger is initially placed at the center of the selected components with an orientation aligned to world coordinates.

The initial dragger orientation can be adjusted in the following ways:

-

1.

To request that a dragger’s initial orientation is always aligned with world coordinates, choose “Interaction ...” from the Settings menu and set initDraggersInWorld to true.

-

2.

Conversely, when transforming a set of point-like objects which lie either within a plane or along a straight line, it can be useful to align the dragger’s orientation to the points. To request this behavior, choose “Interaction ...” from the Settings menu and set alignDraggersToPoints to true.

The transformer tools include:

.![]() Translation:

Translation:

Translates selected components using the translator dragger.

.![]() Rotation:

Rotation:

Rotates selected components using the rotator dragger.

.![]() TransRotation:

TransRotation:

Translates and rotates selected components

using the transRotate dragger. The transformation reference frame

moves with the tool.

.![]() Constrained translation:

Constrained translation:

Translates selected components using the translate dragger while ensuring that

they are constrained to remain on a surface mesh. Only components with

an associated surface mesh (such as FrameMarkers attached to a

RigidBody) can be transformed this way.

.![]() Scaling:

Scaling:

Scales selected components using the transrotator

fixture. Instead of translating, translational drag operations

scale the component along the x, y, or z axes, or in the

x-y, y-z, or z-x planes. Rotational operations, if

used in conjunction with an appropriate modifier key,

can be used to change the orientation of the scaling axes,

as described in 5.2.2.

5.2.1 Constrained transformation

Under the default mouse bindings, pressing the SHIFT modifier key causes drag operations to be constrained to discrete step sizes. Rotation operations are constrained to intervals of five degrees, while translation operations are constrained to either the grid spacing (if a grid is selected, see 3.7), or to a suitable well-rounded number depending on the viewer’s zoom level.

5.2.2 Transformer repositioning

Under the default mouse bindings, pressing the CTRL modifier key causes the dragger fixture to move independently of the selected objects. This allows the transformer frame to be changed relative to the selected objects being manipulated; this is particularly useful for changing the orientation of the scaling directions in the scaling tool.

If a single objects is being transformed (as opposed to a group of selected objects), the application will remember the modified transformer frame if the object is deselected and then reselected. The default frame can be restored by hitting the ’u’ key (Section 5.2.3).

5.2.3 Changing the transformer base frame

By default, a transformer is assigned a local coordinate frame for the object(s) that it is positioning, based on either the object’s own body frame (if it has one), or the objects’ bounding box. This frame will then move with the transformer, and may also move relative to the object(s) if the transformer is repositioned (Section 5.2.2).

Sometimes, it may be desirable to explicitly reset the transformer’s frame. This may be done using the following shortcut keys in the viewer (while a transformer tool is being used and objects are selected):

- w

-

Set the transformer frame to the world coordinate system, allowing subsequent transformations to be performed in world coordinates;

- b

-

Reset the transformer frame to the local frame for the object(s), based on either the object’s body frame or the objects’ bounding box. For single a object, any changes to the transformer frame that were made using the CTRL modifier (Section 5.2.2) will be restored.

- u

-

Reset the transformer frame to the default local frame for the object(s), based on either the object’s body frame or the objects’ bounding box. For single a object, any changes to the transformer frame that were made using the CTRL modifier (Section 5.2.2) will be removed.

5.2.4 Flipping transformer axes forward

Sometimes, a user may discover that a transformer’s frame is inconveniently oriented, with one or more axes directed away from the viewer window, obscuring them and making the transformer difficult to use. This can be mitigated by hitting the ’f’ key in the viewer, which will cause the axes of any active transformer to be flipped so that they are directed toward the viewer window (Figure 25).

|

|

5.2.5 Resizing transformers

ArtiSynth will try to automatically set a transformer’s dragger fixture to an appropriate size. In some cases, the user may wish to change this size, which may be done using the following shortcut keys in the viewer (while a transformer tool is being used and objects are selected):

- CTRL u or UP_ARROW

-

Increases the transformer size.

- CTRL d or DOWN_ARROW

-

Decreases the transformer size.

The default size can be restored by hitting the ’u’ key (Section 5.2.3).

5.3 Pull manipulation

.![]() Pull tool:

Pull tool:

Pulls on certain components using a spring-like force

when simulation is running.

Selecting the pull tool allows a user to interactively apply a spring-like force to certain component types by clicking on it and then dragging (Figure 26). Double clicking on the component adds a pull point that persists between mouse clicks; to remove the pull point, double click on the viewer background.

The pull tool works on points, rigid bodies, FEM models, or any other component that implements the PointAttachable interface and has a surface mesh. Pull manipulation is only effective when simulation is running. It works by adding a special PullController to the current root model’s set of controllers. When attached to the root model, the controller attempts to estimate an appropriate spring stiffness based on the overall mass and dimensions of the first underlying MechModel.

If necessary, the pull tool’s stiffness setting can also be adjusted manually by selecting PullController > properties in the Settings menu. Render properties for the pull controller can be set from this menu also.

5.4 Marker tool

.![]() Marker tool:

Marker tool:

Adds point markers to certain components.

Selecting the marker tool allows a user to interactively add point markers to various components in the model.

Markers can be added by double-clicking on rigid bodies, FEM models, and other components that implement the IsMarkable interface.

Markers are typically added to a component’s surface mesh, and in such cases it is necessary that this surface mesh be visible. For FEM models in particular, the surfaceRendering property should be set to something other than None. To ensure this is the case, select the FEM model, right-click and choose “Edit properties ...”, and examine the setting for surfaceRendering. An FEM model can sometimes appear to have a visible surface mesh, even if it doesn’t, if its elementWidgetSize property is close to 1.

The markers themselves are added to the current root model at a location that depends on the component being marked:

-

•

Rigid bodies: marker is added to the frameMarker list for the body’s parent MechModel;

-

•

FEM models: marker is added to the FEM model’s marker list;

-

•

IsMarkable components: marker is added to the root model’s marker list (which is created on demand if needed).

In order for added markers to be visible, the component list into which they are placed needs to be visible, with its point rendering properties set to appropriate values. That usually means that pointStyle is set to SPHERE or CUBE, with pointRadius set to a value commensurate with the model’s dimensions, or pointStyle is set to POINT, with pointSize set to a sufficiently large value in pixels. If not set within the list itself, the point rendering properties will be inherited from ancestor components. For example, if a MechModel’s point render properties are set for good visibility, then all points within subcomponents will be visible unless these setting have been overridden at a lower point in the hierarchy.

If markers are not appearing when using the marker tool, use the navigation panel to open the component list to which the markers are added (as described above). Verify that markers are actually being appended to the end of the list. If they are not, ensure that the component’s surface mesh is visible. If they are, select the list itself, right-click, and choose “Edit render props ...”. Check that visible is true, and that pointStyle and pointRadius (or pointSize) are set appropriately.

Once created, markers can be removed by selecting them and choosing Delete from the context menu.

6 Editing Properties

Most ArtiSynth model components have properties which can be changed onscreen through the graphical interface. Properties include a diverse set of attributes ranging from stiffness and damping for AxialSprings, position and velocity for particles and rigid bodies, or whether or not a component is dynamic.

The underlying software architecture of the property interface is

described in the Properties chapter of the

Maspack Reference Manual.

6.1 Property panels

To edit properties for a set of components, select the components in question, then right-click in either the viewer or the navigation panel, and select Edit properties. This will create a property panel for all properties which are common to the selected components. All typical property panel is shown in Figure 27.

Property panels are initialized with the current values of the selected components, providing a view of the current property state. A blank property value will be displayed when more than one component is selected and the corresponding property value differs across components.

Some properties are read only. In this case, the corresponding widget in the property panel will display the value but will be disabled.

Property panels are non-modal and persistent. They can be deleted by closing them or clicking the OK button. Clicking the Cancel button will cause the properties to be reset to their values at the time to panel was created.

Normally, a property panel will refresh its widget values whenever the

model view is rerendered. In particular, this will happen repeatedly

while simulation is running. To disable the automatic refresh, click

the live updating button

![]() at the lower

left of the panel.

at the lower

left of the panel.

6.1.1 Inheritable properties

Some properties are inheritable. The value of an inheritable property can be explicitly set or it can be inherited. If inherited, then it inherits its value from ancestor components further up the hierarchy. More specifically, if a property’s value is inherited, then the value is obtained from the nearest ancestor in which the same property exists and is explicitly set. If no such ancestor exists, then the property is set to a default value.

The inherited/explicit status of an inheritable property is controlled by an additional button placed at the left of the property widget (Figure 28). Clicking this button toggles the inherited/explicit status. If set to inherited, then the property’s value is determined from the hierarchy and the updated value is placed in the widget. Setting the value in the widget itself will cause the inheritable status to be set to explicit, and the value of inherited instances of the same property in descendant nodes will be updated accordingly.

6.2 Render properties

Render properties are associated with any component that is renderable. They are defined in the class RenderProps. Because of their complexity, they are adjusted through a separate panel from the standard property panel.

To adjust the property panel for a set of components, select the components in question, using either the viewer window or navigation panel, and then right click in either the viewer or the navigation panel. Several options may appear in the context menu:

- Edit render props

-

- Clear render props

-

This will actually remove the render properties from the selected components (i.e., their render properties will be set to null). Nominally, this means that the components will not be rendered, unless their parents take responsibility for rendering children without render properties. The latter behavior is common for lists of particles, springs, finite elements, etc., in order to avoid the need for defining render properties in a large number of objects.

- Set visible

-

This option will appear if any of the selected objects are invisible. Selecting it will set the render properties so that all components are visible.

- Set invisible

-

This option will appear if any of the selected objects are visible. Selecting it will set the render properties so that all components are invisible.

6.2.1 Render property settings

There are a large number of render property settings. Loosely speaking, they are divided into generic settings, along with those related to faces, lines, and points. How these are used depends on what is being rendered. Mesh rendering typically uses the face settings, along with the line settings to render edges if the drawEdges property is set true. Line settings are also used for rendering axial springs and the edges of FEM elements. Point settings are used for rendering any subclass of Point, including Particle and FemNode.

Not all render properties may appear in a render panel; usually, only those properties relevant to the selected components will be presented.

- Generic properties:

-

- visible:

-

Whether or not the component is visible.

- alpha:

-

The transparency for polygonal faces (range 0 to 1. Default is 1, for opaque).

- shading:

-

How polygons are shaded (FLAT, SMOOTH, METAL and NONE). For viewer implementations there may be no difference between SMOOTH and METAL.

- shininess:

-

Shininess parameter for polygons (range 0 to 128). Default is 32.

- specular:

-

If not null, specifies the specular reflectance color.

- Face related properties:

-

- faceStyle:

-

Which polygonal faces are drawn (FRONT, BACK, FRONT_AND_BACK, NONE).

- faceColor:

-

Color used for drawing faces.

- backColor:

-

Color used for drawing backs of faces. If null, faceColor is used.

- drawEdges:

-

If true, face edgesof the polygons are drawn explicitly.

- Texture mapping properties:

-

- colorMap:

-

If not null, specifies the image source file and properties for color mapping.

- normalMap:

-

If not null, specifies the image source file and properties for normal mapping.

- bumpMap:

-

If not null, specifies the image source file and properties for bump mapping.

- Edge related properties:

-

- edgeColor:

-

The color for edges.

- edgeWidth:

-

Edge width in pixels.

- Line related properties:

-

- lineStyle:

-

How lines are drawn (CYLINDER, LINE, or SPINDLE).

- lineColor:

-

The color for lines.

- lineWidth:

-

Line width in pixels when LINE style is selected.

- lineRadius:

-

Cylinder radius when CYLINDER or SPINDLE style is selected.

- Point related properties:

-

- pointStyle:

-

How points are drawn (SPHERE or POINT).

- pointColor:

-

The color for points.

- pointSize:

-

Point size in pixels when POINT style is selected.

- pointRadius:

-

Sphere radius used when SPHERE style is selected.

A typical panel for editing render properties is shown in Figure 29. Texture mapping properties, if present, are normally hidden by default and can be exposed by clicking on the expand... button.

7 The Timeline

The timeline is a panel that provides “play” controls for starting and stopping the simulation, and allows the user to graphically arrange temporal sequences of probes and waypoints to control and monitor the simulation. If not initially visible, its visibility can be toggled by hitting the ‘t’ key from within the viewer (Section 3.12).

7.1 Probes and waypoints

ArtiSynth allows models to connect to special components, known as probes, which can either supply input values or monitor output values over time as the simulation proceeds. Probes attached to simulation inputs are known as input probes (class InputProbe), while those attached to outputs are known as output probes (class OutputProbe). Each probe has a start time and a stop time, and implements an apply(t0,t1) method that supplies (or collects) data for the simulation step between time t0 and t1. Probes are described in more detail, along with specifics about how to code them into applications, in the “Simulation Control” chapter of the ArtiSynth Modeling Guide.

The most commonly used probe subclasses are NumericInputProbe and NumericOutputProbe, each of which is associated with a vector of floating point values that are interpolated over time. This data is usually connected to various model component properties, and used to either set (for input probes) or collect (for output probes) the values of those properties. The size of the vector is known as the probe’s vector size and matches the properties that the probe is connected to. For example, a probe controlling a single muscle excitation value will have a vector size of one, whereas a probe collecting the 3D velocity of a point will have a vector size of three.

Within a numeric probe, data is defined by a temporal sequence of knots points which give the vector values at prescribed times, with values in between determined by interpolation (Section 7.5.7). For input probes, the knot density is often sparse, whereas for output probes it matches the sample rate at which data is collected, which is usually the simulation step size.

Input and output probes are arranged and displayed graphically in the timeline, within a set of tracks (Section 7.4). Each probe is displayed as a bar within one of these tracks. The display for numeric probes can also be expanded to show a graph of the numeric data (Section 7.5).

ArtiSynth allows models to set temporal waypoints, which are designated times at which the model state is saved during simulation. This allows the simulation to be later reset to that time without having to recompute the simulation from the beginning. A special type of waypoint is known as a breakpoint, which causes the simulation to pause when it is reached. The timeline displays the waypoints, and allows them to be created and edited (Section 7.3).

7.2 Basic timeline structure

The basic structure of the timeline is shown in Figure 30.

The toolbar at the top contains the following widgets:

- Zoom controls

-

Shrinks or expands the timescale.

- Play controls

-

Starts, pauses, or resets the simulation.