11.1 Implementation

This section describes the technical details of the ArtiSynth skinning

mechanism. A skin mesh is implemented using a

SkinMeshBody, which contains a

base mesh and references to a set of underlying dynamic master

bodies. A master body can be either a

Frame (of which

RigidBody is a subclass), or a

FemModel3d. The positions of the

mesh vertices (along with markers and other points that can be

attached to the skin mesh) are determined by a weighted sum of

influences from each of the ![]() master bodies, such that as the latter

move and/or deform, the vertices and attached points deform as

well. More precisely, for each master body

master bodies, such that as the latter

move and/or deform, the vertices and attached points deform as

well. More precisely, for each master body

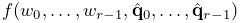

![]() , let

, let ![]() be the weighting factor and

be the weighting factor and

![]() the connection function that describes the

contribution of body

the connection function that describes the

contribution of body ![]() to the position of the vertices (or attached

points) as a function of its generalized coordinates

to the position of the vertices (or attached

points) as a function of its generalized coordinates ![]() . Then if

the position of a vertex (or attached point) is denoted by

. Then if

the position of a vertex (or attached point) is denoted by ![]() and

its initial (or base) position is

and

its initial (or base) position is ![]() , we have

, we have

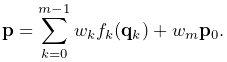

|

(11.1) |

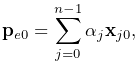

The weight ![]() in the last term is known as the base weight

and describes an optional contribution from the base position

in the last term is known as the base weight

and describes an optional contribution from the base position ![]() .

Usually

.

Usually ![]() , unless the vertex is not connected to any

master bodies, in which case

, unless the vertex is not connected to any

master bodies, in which case ![]() , so that the vertex is anchored

to its initial position.

, so that the vertex is anchored

to its initial position.

In general, connection weights ![]() are computed based on the

distances

are computed based on the

distances ![]() between the vertex (or attached point) and

each master body

between the vertex (or attached point) and

each master body ![]() . More details on this are given in Sections

11.2 and 11.3.

. More details on this are given in Sections

11.2 and 11.3.

For Frame master bodies, the connection function is one associated with various rigid body skinning techniques known in the literature. These include linear, linear dual quaternion, and iterative dual quaternion skinning. Which technique is used is determined by the frameBlending property of the SkinMeshBody, which can be queried or set in code using the methods

where FrameBlending is an enumerated type defined by SkinMeshBody with the following values:

- LINEAR

-

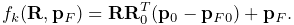

Linear blending, in which the connection function

implements a

standard rigid connection between the vertex and the frame

coordinates. Let the frame’s generalized coordinates

implements a

standard rigid connection between the vertex and the frame

coordinates. Let the frame’s generalized coordinates  be given

by the

be given

by the  rotation matrix

rotation matrix  and translation vector

and translation vector  describing its pose, with its initial pose given by

describing its pose, with its initial pose given by  and

and

. The connection function

. The connection function  then takes the form

then takes the form

(11.2) Linear blending is faster than other blending techniques but is more prone to pinching and creasing artifacts in the presence of large rotations between frames.

- DUAL_QUATERNION_LINEAR

-

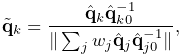

Linear dual quaternion blending, which is more computationally expensive but typically gives better results than linear blending, and is described in detail as DLB in [8]. Let the frame’s generalized coordinates

be given by the dual-quaternion

be given by the dual-quaternion

(describing both rotation and translation), with the

initial pose given by the dual-quaternion

(describing both rotation and translation), with the

initial pose given by the dual-quaternion  . Then define

the relative dual-quaternion

. Then define

the relative dual-quaternion  as

as

(11.3) where the denominator is formed by summing over all master bodies

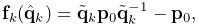

which are frames. The connection function

which are frames. The connection function  is then

given by

is then

given by

(11.4) where we note that a dual quaternion multiplied by a position vector yields a position vector.

- DUAL_QUATERNION_ITERATIVE

-

Dual quaternion iterative blending, which is a more complex dual quaternion technique described in detail as DIB in [8]. The connection function for iterative dual quaternion blending involves an iterative process and is not described here. It also does not conform to (11.1), because the connection functions

for the Frame master

bodies do not combine linearly. Instead, if there

are

for the Frame master

bodies do not combine linearly. Instead, if there

are  Frame master bodies, there is a single

connection function

Frame master bodies, there is a single

connection function

(11.5) that determines the connection for all of them, given their weighting factors

and generalized coordinates

and generalized coordinates  .

Iterative blending relies on two parameters: a blend tolerance, and a

maximum number of blend steps, both of which are controlled by the

SkinMeshBody properties DQBlendTolerance and DQMaxBlendSteps, which have default values of

.

Iterative blending relies on two parameters: a blend tolerance, and a

maximum number of blend steps, both of which are controlled by the

SkinMeshBody properties DQBlendTolerance and DQMaxBlendSteps, which have default values of  and

and  .

.Iterative dual quaternion blending is not completely supported in ArtiSynth. In particular, because of its complexity, the associated force and velocity mappings are computed using the simpler computations employed for linear dual quaternion blending. For the examples shown in this chapter, iterative dual quaternion gives results that are quite close to those of linear dual quaternion blending.

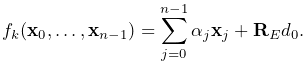

For FEM master bodies, the connection works by tying each vertex (or

attached point) to a specific FEM element using a fixed-length offset

vector ![]() that rotates in conjunction with the element. This is

illustrated in Figure 11.2 for the case of a

single FEM master body. Starting with the initial vertex position

that rotates in conjunction with the element. This is

illustrated in Figure 11.2 for the case of a

single FEM master body. Starting with the initial vertex position

![]() , we find the nearest point

, we find the nearest point ![]() on the nearest FEM

element, along with the offset vector

on the nearest FEM

element, along with the offset vector ![]() . The point

. The point ![]() can be expressed as the weighted

sum of the initial element nodal positions

can be expressed as the weighted

sum of the initial element nodal positions ![]() ,

,

|

(11.6) |

where ![]() is the number of nodes and

is the number of nodes and ![]() represent the

(constant) nodal coordinates. As the element moves and deforms, the

element point

represent the

(constant) nodal coordinates. As the element moves and deforms, the

element point ![]() moves with the nodal positions

moves with the nodal positions ![]() according

to the same relationship, while the offset vector

according

to the same relationship, while the offset vector ![]() rotates

according to

rotates

according to ![]() , where

, where ![]() is the rotation of the

element’s coordinate frame

is the rotation of the

element’s coordinate frame ![]() with respect to its initial

orientation. The connection function

with respect to its initial

orientation. The connection function ![]() then takes the form

then takes the form

|

(11.7) |

![]() is determined by computing a polar decomposition

is determined by computing a polar decomposition ![]() on the deformation gradient

on the deformation gradient ![]() at the element’s center. We note that

the displacement

at the element’s center. We note that

the displacement ![]() is only rotated and so the distance

is only rotated and so the distance ![]() of the vertex from the element remains constant. If the

vertex is initially on or inside the element, then

of the vertex from the element remains constant. If the

vertex is initially on or inside the element, then ![]() and

(11.7) takes the form of a standard point/element

attachment as described in 6.4.3.

and

(11.7) takes the form of a standard point/element

attachment as described in 6.4.3.

While it is sometimes possible to determine weights

that control a vertex position outside an element, without the need for an offset vector

, the resulting vertex positions tend to be very sensitive to element distortions, particularly when the vertex is located at some distance. Keeping the element-vertex distance constant via an offset vector usually results in more plausible skinning behavior.