9.6 Tuning the Wrapping Behavior

Wrappable segments are implemented internally using artificial linear elastic forces to draw the knots together and keep them from penetrating obstacles. These artificial forces are invisible to the simulation: the wrapping segment has no mass, and the knot forces are used to create what is essentially a first order physics that “shrink wraps” each segment around the obstacles at the beginning of each simulation step, forming a shortest-distance geodesic curve from which the wrapping contact points A and B are calculated. This process is now described in more detail.

Assume that a wrappable segment has ![]() knots, indexed by

knots, indexed by ![]() , each located at a position

, each located at a position ![]() . Two types of

artificial forces then act on each knot: a wrapping force

that pulls it closer to other knots, and contact forces that

push it away from wrappable obstacles. The wrapping force is given by

. Two types of

artificial forces then act on each knot: a wrapping force

that pulls it closer to other knots, and contact forces that

push it away from wrappable obstacles. The wrapping force is given by

where ![]() is the wrapping stiffness. To determine the contact

forces, we compute, for each wrappable, the knot’s distance to the

surface

is the wrapping stiffness. To determine the contact

forces, we compute, for each wrappable, the knot’s distance to the

surface ![]() and associated normal direction

and associated normal direction ![]() , where

, where ![]() implies that the knot is inside. These quantities are determined

either analytically (for analytic wrappables, Table

9.1), or using a signed distance grid (for

general wrappables, Section 9.3). The

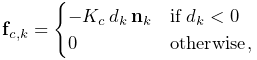

contact forces are then given by

implies that the knot is inside. These quantities are determined

either analytically (for analytic wrappables, Table

9.1), or using a signed distance grid (for

general wrappables, Section 9.3). The

contact forces are then given by

|

where ![]() is the contact stiffness.

is the contact stiffness.

The total force ![]() acting on each knot is then given by

acting on each knot is then given by

where the latter term is the sum of contact forces for all wrappables.

If we let ![]() and

and ![]() denote the aggregate position and force vectors

for all knots, then computing the wrap path involves finding the

equilibrium position such that

denote the aggregate position and force vectors

for all knots, then computing the wrap path involves finding the

equilibrium position such that ![]() . This is done at the

beginning of each simulation step, or whenever updateWrapSegments() is called, and

is achieved iteratively using Newton’s method.

If

. This is done at the

beginning of each simulation step, or whenever updateWrapSegments() is called, and

is achieved iteratively using Newton’s method.

If ![]() and

and ![]() denote the positions and forces at iteration

denote the positions and forces at iteration ![]() ,

and

,

and

denotes the local force derivative (or “stiffness”), then the basic Newton update is given by

In practice, to help deal with the nonlinearities associated with contact, we use a damped Newton update,

| (9.1) |

where ![]() is a constant wrap damping parameter, and

is a constant wrap damping parameter, and ![]() is

an adaptively computed step size adjustment. The computation of

(9.1) can be performed quickly, in

is

an adaptively computed step size adjustment. The computation of

(9.1) can be performed quickly, in ![]() time, since

time, since ![]() is a block-tridiagonal matrix, and the number of

iterations required is typically small (on the order of 10 or less),

particularly since the iterative procedure continues across simulation

steps and so

is a block-tridiagonal matrix, and the number of

iterations required is typically small (on the order of 10 or less),

particularly since the iterative procedure continues across simulation

steps and so ![]() does not need to be brought to

does not need to be brought to ![]() for any given

step. The maximum number of Newton iterations used for each

time step is

for any given

step. The maximum number of Newton iterations used for each

time step is ![]() .

.

Again, it is important to understand the artificial knot forces

described here are separate from the physical spring/muscle tension forces

discussed in Sections 3.1.1 and 4.5.1, and only facilitate the computation of each wrappable segment’s path around obstacles.

The default values for the wrapping parameters are ![]() ,

, ![]() ,

, ![]() , and

, and ![]() , and these often give

satisfactory results without the need for modification. However, in

some situations the default muscle wrapping may not perform adequately

and it is necessary to adjust these parameters. Problems may include:

, and these often give

satisfactory results without the need for modification. However, in

some situations the default muscle wrapping may not perform adequately

and it is necessary to adjust these parameters. Problems may include:

-

•

The wrapping path does not settle down and tends to “jump around”. Solutions include increasing the damping parameter

or

the maximum number of wrap iterations

or

the maximum number of wrap iterations  . For general wrapping

surfaces (Section 9.3), one should also

ensure that the surface is sufficiently smooth.

. For general wrapping

surfaces (Section 9.3), one should also

ensure that the surface is sufficiently smooth. -

•

A wrapping surface is too thin and so the wrapping path “jumps through” it. Solutions include increasing the damping parameter

, increasing the number of knots in the segment, or

decreasing the simulation step size. An alternative approach is to use

an alternative wrapping surface

(Section 9.5) that is thicker and

better behaved.

, increasing the number of knots in the segment, or

decreasing the simulation step size. An alternative approach is to use

an alternative wrapping surface

(Section 9.5) that is thicker and

better behaved.

Wrapping parameters are exported as properties of MultiPointSpring and MultiPointMuscle, and may be changed in code (using their set/get accessors), or interactively, either by exposing them through a control panel, or by selecting the spring/muscle in the GUI and choosing Edit properties ... from the right-click context menu. Property values include:

- wrapStiffness

-

Wrapping stiffness

between knot points

(default value 1). Since the wrapping behavior is determined by the

damping to stiffness ratio, it is generally not necessary to

change this value.

between knot points

(default value 1). Since the wrapping behavior is determined by the

damping to stiffness ratio, it is generally not necessary to

change this value. - wrapDamping

-

Damping factor

(default

value 10). Increasing this value relative to

(default

value 10). Increasing this value relative to  results in wrap

path motions that are smoother and less likely to penetrate obstacles,

but which are also less dynamically responsive. Applications generally

work with damping values between 10 and 100 (assuming

results in wrap

path motions that are smoother and less likely to penetrate obstacles,

but which are also less dynamically responsive. Applications generally

work with damping values between 10 and 100 (assuming  ).

). - contactStiffness

-

Contact stiffness

used to resolve obstacle

penetration (default value 10). It is generally not necessary

to change this value. Decreasing it will increase the distance that

knots are permitted to penetrate obstacles, which may result in

a slightly more stable contact behavior.

used to resolve obstacle

penetration (default value 10). It is generally not necessary

to change this value. Decreasing it will increase the distance that

knots are permitted to penetrate obstacles, which may result in

a slightly more stable contact behavior. - maxWrapIterations

-

Maximum number of Newton iterations

per time step (default value 10). If the wrapping

simulation exhibits instability, particularly with regard to obstacle

contact, increasing the number of iterations (to say 100) may help.

per time step (default value 10). If the wrapping

simulation exhibits instability, particularly with regard to obstacle

contact, increasing the number of iterations (to say 100) may help.

In addition, MultiPointSpring and MultiPointMuscle also export the following properties to control the rendering of knot and A/B points:

- drawKnots

-

If true, renders the knot points in each wrappable segment. This can be useful to visualize the knot density. Knots are rendered using the style, size, and color given by the pointStyle, pointRadius, pointSize, and pointColor values of the spring/muscle’s render properties.

- drawABPoints

-

If true, renders the A/B points. These are the first and last points of contact that a wrap segment makes with each wrappable, and correspond to the points where the spring/muscle’s tension acts on that wrappable (Section 9 and Figure 9.4). A/B points are rendered using the style and size given by the pointStyle, pointRadius (

) and pointSize values of the spring/muscle’s render

properties, and the color given by the ABPointColor property.

) and pointSize values of the spring/muscle’s render

properties, and the color given by the ABPointColor property.